Hi guys, my first post here and unfortunatly its not a good one...

Just got a 1990 Fisher 14 SV-14 DLX with a 1999 Johnson J25RLEEN 25HP engine from a outboard mechanic. Gave me 30-day warranty on engine/boat. Took it out last week for a test run and had several issues.

1. Primer/choke pump O-rings messed up and will not prime cold engine, also was leaking.

Removed and replaced O-rings and works like a charm now.

2. When first started water was coming out of back at idle not too strong but when it warmed up it would not shoot water out of the back at idle and the engine got really hot and burned my wrist when I was trying to see if the water lines were clear. It would start to spray when I would get more speed but again very hot water coming out.

We removed the lower unit and to my surprise the impeller/water pump was brand new. We also removed the head cover to check the thermostat and it was new also. I noticed that they were not using the right grommet #70(302497) to seal the pump to the water tube. Could this be the cause of not getting enough water up to block? Also the impeller housing spacer #64(326692) was melted on the top portion. The mech says "it's ok, we wil cut the top portion of the spacer and the grommet should work". I'm just going to get the right grommet and a new spacer.

3. At WOT the engine really didn't have much power and would bog down sometimes.

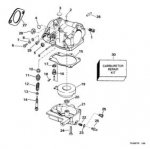

I suspected the primer/choke pump O-ring leaking and suppling the engine with more fuel resulting in less power(fixed now). Compression is 85lbs on both cylinders. I noticed the foam insulation underneath the cowling is peeling off and some was in the carb throat. The carb was cleaned/tuned right in front of me by the mech before I took it out. I decided to clean it again last night and everything was very clean but I noticed that insted of the core plug #4(326692) there is a screen on both side of the carb. The diagram only shows one side and its a core plug. Why would there be a screen insted of a core plug? Also the low speed needle was set to 2 1/2 by the mech. Should'nt it be 1 1/2 turns out?

Anyone got any suggestions?

Thanks

Just got a 1990 Fisher 14 SV-14 DLX with a 1999 Johnson J25RLEEN 25HP engine from a outboard mechanic. Gave me 30-day warranty on engine/boat. Took it out last week for a test run and had several issues.

1. Primer/choke pump O-rings messed up and will not prime cold engine, also was leaking.

Removed and replaced O-rings and works like a charm now.

2. When first started water was coming out of back at idle not too strong but when it warmed up it would not shoot water out of the back at idle and the engine got really hot and burned my wrist when I was trying to see if the water lines were clear. It would start to spray when I would get more speed but again very hot water coming out.

We removed the lower unit and to my surprise the impeller/water pump was brand new. We also removed the head cover to check the thermostat and it was new also. I noticed that they were not using the right grommet #70(302497) to seal the pump to the water tube. Could this be the cause of not getting enough water up to block? Also the impeller housing spacer #64(326692) was melted on the top portion. The mech says "it's ok, we wil cut the top portion of the spacer and the grommet should work". I'm just going to get the right grommet and a new spacer.

3. At WOT the engine really didn't have much power and would bog down sometimes.

I suspected the primer/choke pump O-ring leaking and suppling the engine with more fuel resulting in less power(fixed now). Compression is 85lbs on both cylinders. I noticed the foam insulation underneath the cowling is peeling off and some was in the carb throat. The carb was cleaned/tuned right in front of me by the mech before I took it out. I decided to clean it again last night and everything was very clean but I noticed that insted of the core plug #4(326692) there is a screen on both side of the carb. The diagram only shows one side and its a core plug. Why would there be a screen insted of a core plug? Also the low speed needle was set to 2 1/2 by the mech. Should'nt it be 1 1/2 turns out?

Anyone got any suggestions?

Thanks