Fishermark

Vice Admiral

- Joined

- Oct 19, 2003

- Messages

- 5,627

On the project boat I am working on?. (An early 70?s vintage SeaRay with a Mercruiser inline 6 and pre-alpha outdrive).

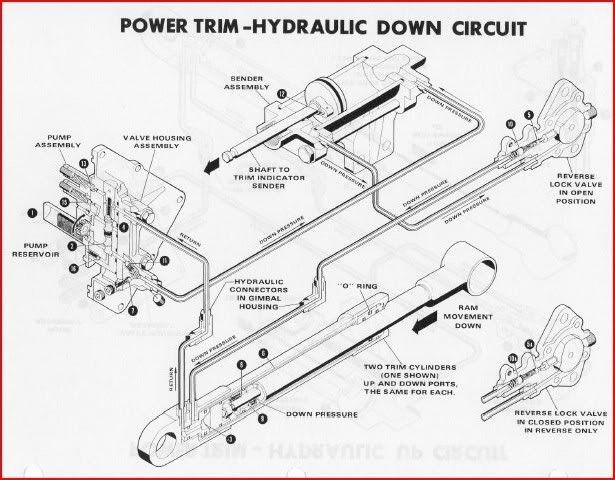

Taking a break from the engine work - (waiting for a new coupler to arrive). Decided to work on the trim and tilt mechanism. After wiring it up and topping it off with fluid, it only works going ?up? not ?down.?

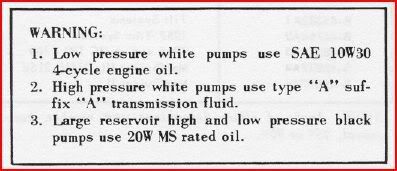

I downloaded the appropriate manual (looks like I did so just in time - I see from another post that the online version has been shut down - is that true?). According to the manual I have a high pressure, large reservoir pump. As noted in the picture below, there are quite a few ?extra? parts that I am not familiar with from my Alpha experience:

Now when I say it doesn?t work going down, what I mean is the pump motor runs, the drive simply doesn?t move. I loosened the trim lines and pushed the unit down, hooked it back up and again, the outdrive will go all the way up to the trailer position, but will not go down at all.

Suggestions???

On a related note, the trim pump calls for ?MS rated 20W oil.? I noted that there was red fluid in the pump currently, which I took to be transmission fluid. I topped it off with transmission fluid. Is it safe to assume that it should work with this - even if that is not the technically correct fluid? (In the manual, it mentions installing a new pump and saying the ?oil in the pump will mix with automatic transmission fluid in cylinders with no ill effect.?) Having said that - what is MS rated 20W oil??

One last note,: in order to get the outdrive in the down position, I had to remove the down trim lines as mentioned. Even then, the outdrive didn?t go down on its own - I had to push it down, and it seemed stiff. Is that normal?

Taking a break from the engine work - (waiting for a new coupler to arrive). Decided to work on the trim and tilt mechanism. After wiring it up and topping it off with fluid, it only works going ?up? not ?down.?

I downloaded the appropriate manual (looks like I did so just in time - I see from another post that the online version has been shut down - is that true?). According to the manual I have a high pressure, large reservoir pump. As noted in the picture below, there are quite a few ?extra? parts that I am not familiar with from my Alpha experience:

Now when I say it doesn?t work going down, what I mean is the pump motor runs, the drive simply doesn?t move. I loosened the trim lines and pushed the unit down, hooked it back up and again, the outdrive will go all the way up to the trailer position, but will not go down at all.

Suggestions???

On a related note, the trim pump calls for ?MS rated 20W oil.? I noted that there was red fluid in the pump currently, which I took to be transmission fluid. I topped it off with transmission fluid. Is it safe to assume that it should work with this - even if that is not the technically correct fluid? (In the manual, it mentions installing a new pump and saying the ?oil in the pump will mix with automatic transmission fluid in cylinders with no ill effect.?) Having said that - what is MS rated 20W oil??

One last note,: in order to get the outdrive in the down position, I had to remove the down trim lines as mentioned. Even then, the outdrive didn?t go down on its own - I had to push it down, and it seemed stiff. Is that normal?