Since getting my motor working, I've used it for several hours on the lake and both the running and starting have improved significantly. That's probably in part due to getting used to how it likes to be treated............however this afternoon I hit a snag. Well, a submerged tree to be precise.

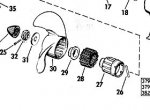

It didn't stop running, but the drive to the prop failed and the prop now spins freely.

What have I likely done and what should I do next?

It didn't stop running, but the drive to the prop failed and the prop now spins freely.

What have I likely done and what should I do next?