Quack Addict

Cadet

- Joined

- May 18, 2009

- Messages

- 25

I am working on a Frankenstein project - it's a 1978 Sea Ray V240 with Mercruiser 260 (Chevy 350) engine. It's getting a new Alpha drive; should be arriving later this week.

I replaced the floor in the boat after I purchased it / knew it needed it before the purchase. While I was had the floor up, I replaced the engine beds (it needed new beds). Problem is, I think my new engine beds are a hair too high based upon the trouble I am having getting the engine aligned. Both front mounts are bottomed out and I can almost get my alignment bar in but eye-balling the centerline of the coupler through the gimbal bearing, it looks like the front of the engine still needs to come down a bit more to elevate the rear.

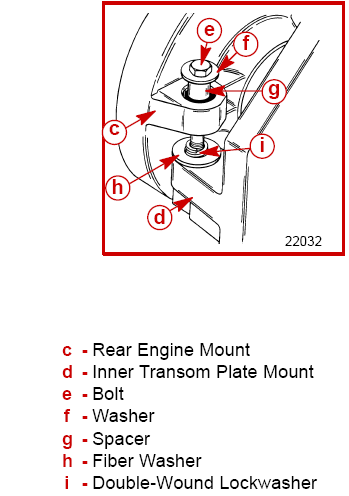

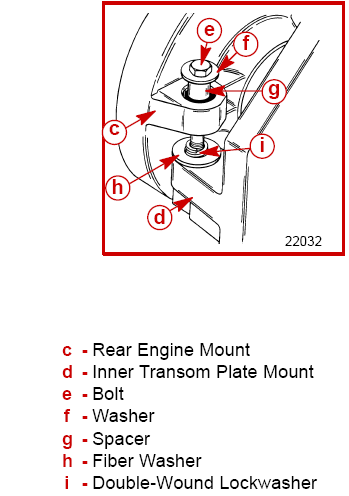

Is it possible / acceptable to shim the rear mounts (stainless washer) to bring the back of the engine up slightly? Based upon the alignment tool, it seems like about 0.040" (1mm) of shim at the rear of the engine would elevate me enough where I could regain some additional adjusement in the front mounts to get proper alignment coupler / gimbal bearing alignment. The shim would go in under "h" - the fiber washer and "i" - the spring - in the picture below:

Am I in the weeds with the thought of shimming the rear mount, or is this an acceptable solution for my current status? I just dumped a lot of $$$ into a new outdrive, the engine is 100% fresh and I want it all to last a good long time... so I am not looking to save a few cents here only to pay dollars later for a tow bill and later repairs. If shimming is unacceptable, why? Is there some sacred relationship between the transom plate and engine bell housing that rules out insertion of a shim between them???

The only alternate solutions I see are modifying the engine beds (requires engine removal) or removing the engine-side half of the front mounts and shaving the bottom face where it sits against the bottom adjusting nut.

Thoughts?

Thanks!

I replaced the floor in the boat after I purchased it / knew it needed it before the purchase. While I was had the floor up, I replaced the engine beds (it needed new beds). Problem is, I think my new engine beds are a hair too high based upon the trouble I am having getting the engine aligned. Both front mounts are bottomed out and I can almost get my alignment bar in but eye-balling the centerline of the coupler through the gimbal bearing, it looks like the front of the engine still needs to come down a bit more to elevate the rear.

Is it possible / acceptable to shim the rear mounts (stainless washer) to bring the back of the engine up slightly? Based upon the alignment tool, it seems like about 0.040" (1mm) of shim at the rear of the engine would elevate me enough where I could regain some additional adjusement in the front mounts to get proper alignment coupler / gimbal bearing alignment. The shim would go in under "h" - the fiber washer and "i" - the spring - in the picture below:

Am I in the weeds with the thought of shimming the rear mount, or is this an acceptable solution for my current status? I just dumped a lot of $$$ into a new outdrive, the engine is 100% fresh and I want it all to last a good long time... so I am not looking to save a few cents here only to pay dollars later for a tow bill and later repairs. If shimming is unacceptable, why? Is there some sacred relationship between the transom plate and engine bell housing that rules out insertion of a shim between them???

The only alternate solutions I see are modifying the engine beds (requires engine removal) or removing the engine-side half of the front mounts and shaving the bottom face where it sits against the bottom adjusting nut.

Thoughts?

Thanks!