mswalter2009

Seaman Apprentice

- Joined

- Jul 6, 2009

- Messages

- 45

Anyone see any issue with my plan to fix the hole? I have worked with fiberglass a good bit so it?s a given that surfaces will be properly cleaned and prepared.

Went out last weekend and someone was sitting in a deck chair in the front of the boat. Hit a big wake and the person and chair slammed down onto the deck. Later when I was cleaning the boat noticed that a chair leg had cracked a hole in the deck. Upon further inspection there was a soft area there. I now have an 11 x 14 inch hole in my deck where I cut back to good wood. The deck consists of about 1/8 inch glass on top of half inch plywood. There is a stringer running through the left side of the hole. About two inches off center. Stringer is fine. Fully encapsulated even on top. Thank goodness. Can?t tell where the water came from. No cracks in the deck and no hardware even close.

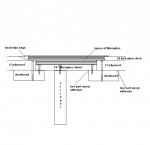

So here?s is where I?m at. I have the glass cut away at 11 x 14 inches. Left about an inch of good wood so the actual hole is smaller. The hole spans a stringer. My plan is to ?

1. Install deadwood around the edges using half inch plywood. Securing to the goodwood using stainless screws counter sunk and also a two part epoxy adhesive. Coat the deadwood with fiberglass. Maybe a couple of coats.

2. Either build or find a quarter inch sheet of fiberglass. Cut a piece to fit in the hole. It will rest on the deadwood.

3. Apply two part epoxy to the deadwood and secure the piece into place with SS screws.

4. Since the deck is half inch plywood and I put a quarter inch piece into the hole I still have some space to build up.

5. Build up the space with pieces of fiberglass mat until I?m just above the glass on the deck.

6. Let it cure and sand it down to even with the deck.

7. blend it in with some grey non stick marine paint.

Boat is an 1984 18? Privateer

Deck is a grey non skid. Not a finished deck.

Thanks

Went out last weekend and someone was sitting in a deck chair in the front of the boat. Hit a big wake and the person and chair slammed down onto the deck. Later when I was cleaning the boat noticed that a chair leg had cracked a hole in the deck. Upon further inspection there was a soft area there. I now have an 11 x 14 inch hole in my deck where I cut back to good wood. The deck consists of about 1/8 inch glass on top of half inch plywood. There is a stringer running through the left side of the hole. About two inches off center. Stringer is fine. Fully encapsulated even on top. Thank goodness. Can?t tell where the water came from. No cracks in the deck and no hardware even close.

So here?s is where I?m at. I have the glass cut away at 11 x 14 inches. Left about an inch of good wood so the actual hole is smaller. The hole spans a stringer. My plan is to ?

1. Install deadwood around the edges using half inch plywood. Securing to the goodwood using stainless screws counter sunk and also a two part epoxy adhesive. Coat the deadwood with fiberglass. Maybe a couple of coats.

2. Either build or find a quarter inch sheet of fiberglass. Cut a piece to fit in the hole. It will rest on the deadwood.

3. Apply two part epoxy to the deadwood and secure the piece into place with SS screws.

4. Since the deck is half inch plywood and I put a quarter inch piece into the hole I still have some space to build up.

5. Build up the space with pieces of fiberglass mat until I?m just above the glass on the deck.

6. Let it cure and sand it down to even with the deck.

7. blend it in with some grey non stick marine paint.

Boat is an 1984 18? Privateer

Deck is a grey non skid. Not a finished deck.

Thanks