I need to remove the decking on my 2001 Fishmaster 176 to get at damaged beams and leaking rivets.

Does anyone know how the side decking is attached? (Side decking covers the compartment filled with foam)

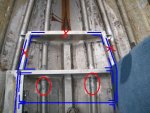

The middle deck is just screwed down but the side deck is covered with vinyl so I can't see how it is attached. It looks looks like it is plywood pop-riveted down through a plate and then to the structural member in the front of the picture (running fore and aft). The seat pedestals also seem to be attached to the plate. How is it attached to the side of the boat? There are screws holding the AL sheet sides to the plywood deck in the back of the picture. Is this all there is?

Many thanks for any input.

Does anyone know how the side decking is attached? (Side decking covers the compartment filled with foam)

The middle deck is just screwed down but the side deck is covered with vinyl so I can't see how it is attached. It looks looks like it is plywood pop-riveted down through a plate and then to the structural member in the front of the picture (running fore and aft). The seat pedestals also seem to be attached to the plate. How is it attached to the side of the boat? There are screws holding the AL sheet sides to the plywood deck in the back of the picture. Is this all there is?

Many thanks for any input.