Re: diode installation

Hello, I figured I'd give a little insight into how a diode works so you can know if you are measuring it correctly.

To measure a diode use the diode setting on a digital multimeter.

For an analog multimeter, use a low value resistance setting and measure it to get the highest voltage across the diode. Also on analog multimeters the positive and negative ends are reversed on resistance readings for how the meter works (Black to anode, Red to cathode to test it working).

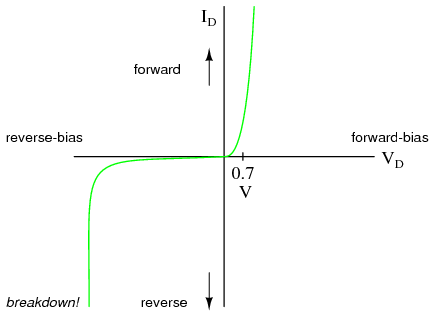

A diode has a 0.7 Volt drop across it in any circuit at almost any positive current draw. This is much different than a resistor where the voltage is directly proportional to current draw. Without a 0.7 volt difference across the diode, very little current will flow (Which will give you wrong readings). After the diode, the wire will be 0.7 volts lower. You can see the picture below to demonstrate, however, that the voltage drop does vary slightly with current. This picture also shows that below 0.7 volts, some current will flow.

So unless your multimeter is providing > 0.7 Volts (assuming silicon diode), then it will not read properly on the resistance setting. Well technically it will never read correctly, but it will give a low resistance with enough voltage.

Also, if the voltage is very high, Maybe > 50 Volts in the opposite direction, current will flow in reverse, this is the breakdown voltage.

An LED diode is the same as a diode except instead of using Silicon they use other materials, such as Silicon carbide for Blue. When current flows across a diode electrons fill places where electrons should be (Called holes), which causes them to change energy levels. When this happens a photon is released. The size of the change in energy levels directly relates to the frequency of the light (or the color).