Re: 21.5' 1990 Campion Fishing machine transom and stringer restore

Ok in the engineering sense, at the factory I would use multiple layesr of ply, 1/4-3/8" and have a metal (hydraulic press) glue jig that is shaped the same curvature as the hull is required to be. The I would laminate/glue and bend/warp the different muli layers of ply with force, heat, steam, and glue. Basically preforming the wood for the transom to what I wanted. Then cut to shape. Seeing you do not have the jig or hydralic press to bend yours, I would go the three separate pieces method.

Mine came from the factory with a three piece construction. Most of the bayliner from the 80's and 90's where done this way. And the transom issues with Bayliners where not due to this three piece constuction system. It was because they did not seal the transom after drilling all the holes in it. So water intruded into the wood and rotted them.

Your champion had one piece from what I can tell from your pics. Seeing you do not have the capability of replicating the factory piece of wood. You are going to have to go the three piece method. IMO

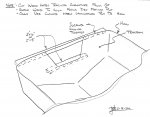

Is it strong enough to hold a 150? Yes if you ensure that stringers and gussets are in place to aid in the structural aspecs of the system you are building. No transom is one piece. They are built out of multiple piece glassed together. The stringers and gusset must be glassed to the hull and transom to become a transom system. Even if you are not going with a three piece design, I would do the gussets and stringers to the best (strusturally) you can. Never hurts to have a strong back bone in a boat! Bring the stringer and gussets as high as you can on the transom. The added hieght will increase your strength by astronomical amounts. Hell Bayline 2302 hang's twin 150hp Forces off transoms with this method of construction.

My sugestion to you is draw up a sketch like the one I had done in my rebuild, put some rough numbers/dimensions to it. Try to show a before and after. Then open a new thread here on Iboats with a weird title and have everyone shot holes in it. Include a few pics on the hull and stringers as it was and as it is now when you do it. That way you will get more exposure to your idea's. And then the experts will start chiming in. Also it will not be in your log thread here with all of your progress on your project.