chriscraft254

Commander

- Joined

- Jun 4, 2011

- Messages

- 2,445

This thread will be to provided information about different style led strips and what there differences are. There is alot of info out there but it can be confusing and is spread all over the place.

I will try and keep this simple because it truly is simple. I personally have been installing these and learning about them for about two years now. My refurb thread shows what I have done on my boat.

Anyone can install these with a little knowledge and knowing what to order.

Not all the information given will be specific to a certain brand or manufacturer. I would say 90 percent of the led strip lights provided to us in the markets come from overseas like Honk Kong, China etc. Even if it is a usa company, in most cases they will be providing you with lights from overseas. I have no affiliation with any manufacturers or companies that sell these lights. The information I am providing is strickly from what I have learned through my experiences.

First and formost if you are using led strip lights on your boat, you need water proof lighting. Even on interior lighting, I would use waterproof lighting as humidity and other variables like salt etc can corrode the copper that the strips are made of if not protected. Will get into this more later.

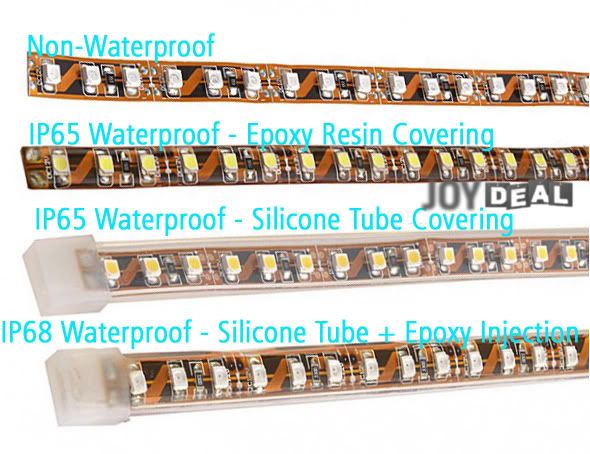

Here is the first diagram I would like to share with you.

Differnent style strip lights-

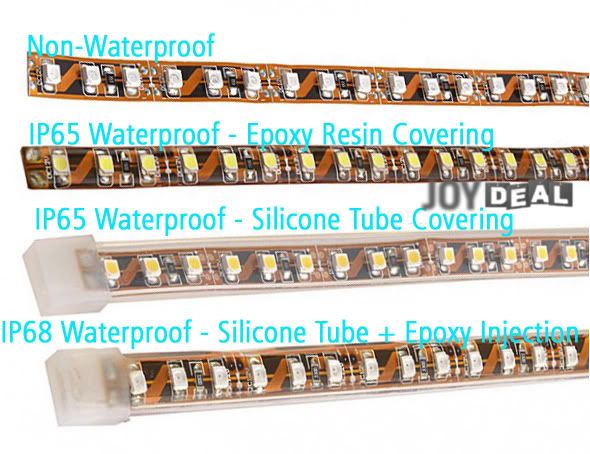

Above you can see there are many different styles available. The top one is the one you "don't" want for your boat. When placing orders, make sure it says water proof or don't buy them.

The IP65 resin strips are great for outdoor use and bend well. They are offered in white, black and the copper color you see above. If bent to many times, you will break the connection in the copper,like if you try installing them more than once. These all come with self stick adhesive on the back of the strip. The self stick adhesive is a one shot deal, get it right the first time because if you pull the strip off, chances are the self stick will not last and you take the chance on crimping the light strip.

The IP65 silicone tube covered or what I like to call "sleaved" are also water proof but have no injected silicone or resin. It is simply the strip covered with a silicone sleave or tube as they call it, that protects the strip. These were the first style strips that I bought and they have lasted for two years so far installed on my boat.

The downfall of the IP65 silicone tube/sleaved is you must make sure the end caps are installed and the silicone is injected into the ends for sealing. Some of these strips come with a injection syringe and some don't. You can simply fill the end cap with silicone and slide it on the ends to seal. Most strips do not come with extra end caps, so if cutting the strip for multiple locations, you will want to purchase extra end caps for a clean a protected install.

The IP68 is epoxy resined with a silicone tube over the top of the resin incased strip. These can be used under water, they are fully protected from the elements. They are the only ones that should be used for underwater applications. If used underwater, you must make sure all connections are sealed carefully as well.

All the above are offered in different color strips, and also in one color, or "rgb" color which I will talk about more later in the thread.

Different light numbers per strip and the sizes of those lights.

As seen above, there are two different size lights ofered in these strips. When ordering, make sure you get what you want.

The SMD 3528 LED strip light has smaller lights than the SMD 5050 strip lights. They are also cheaper to buy if the number of lights per meter of light strip is the same. Will talk more on this down in the thread.

The SMD 5050 LED strip light has larger lights than the SMD 3528 strip lights. The 5050 lights are individually brighter than the 3528 LED strip lights individually are. The 5050 lights can be up to 3 times brighter per light than the 3528 sized lights.

Now, the reason I said individually is, both the SMD 3528 LED strip and the 5050 Led strip, is offered with either 30 lights per meter or 60 lights per meter. The more lights you have the smoother the light will be and less hot spots you will have after installation.

When I say hot spots, with the smaller led lights at 30 lights per meter will give you good lighting, but they are smaller lights and can give you dull or bright spots where the light isn't filled between lights on the strip. And as said before are not as bright as the 5050 lights.

With the 60 lights per meter, you will have less hot spots and more light output per strip. Both the 3528 and the 5050 are offered with the 60 lights per meter but are harder to find online and are more expensive, but still reasonable.

Not to confuse anyone, but a 60 light per meter 3528 strip will probably be better than a 5050 light strip with only 30 lights per meter or atleast just as good.

To recap, the less lights (30 per meter) and the less the number in front of the light strip (3528) the least expensive they will be to purchase but are not the best. These lights are the most economical and will give the average person a thrill once installed. For led inthusiast like myself, I want the best light available and the best look. So future purchases will all be IP68, 5050 with 60 lights per meter.

Static one color or RGB light strips. .

This is where things get interesting. Each light strip wether it be 3528 or 5050 is offered in a one color or multi-color (rgb).

The one color light strip is simple. If you only want one color like red, white, blue, purple, green, etc, then you order that particular color when ordering your light strips. These light strips can simply be controlled by an on/off switch. I would suggest a dimmer atleast if you buy one color. Actually I would suggest you spend a little more mula and get some RGB lights so you always have the choice of different colors.

Remember red is the only color good for underway if you plan on using these while on the move. Red does not effect your night vision.

RGB light strip means (RED,GREEN,BLUE), with these lights you can pretty much turn any color you chose depending on the RF controller that you buy to go along with them.

The RGB light strips must be controlled by a Rf controller with IR remote controller. These controllers come as a package deal or can be bought seperate from the rgb lights strips.

All RGB, RF controllers, and there related IR remotes are not created equal. Some will turn your lights 3 different colors, some will turn them 7 different colors, some will turn your light strips like 20 different colors. I like having the most options available per dollars spent.

RGB RF controllers offer different selection of control. Static for each color, blinking, fade, dimming etc etc etc. Different controllers will have more or less control options depending on what you select to purchase.

RGB controllers are also all different in the way they except your wiring for those rgb lights. The controller and remote I prefer at this time is this one. I have a couple others and this one is the easest to install wires into from the strip lights and battery.

Many of you have seen the back of a home stereo system where your speaker wires just get slid into a connector that has either a spring loaded arm that holds the wire connection tight or a screw type that tightens down on the stripped wire. This controller is just like the latter, it has a screw you loosen, stick in the wire, and tighten the screw down on the wire installed. The controller is marked r,g, b and V+. These mark the color coded wire to the proper input to the RF controller and the hot and negative inputs are also marked.

Wiring your system.

I won't get into to many specifics here because it will be up to the individual boat owner on how they want the lighting system wired into there boat.

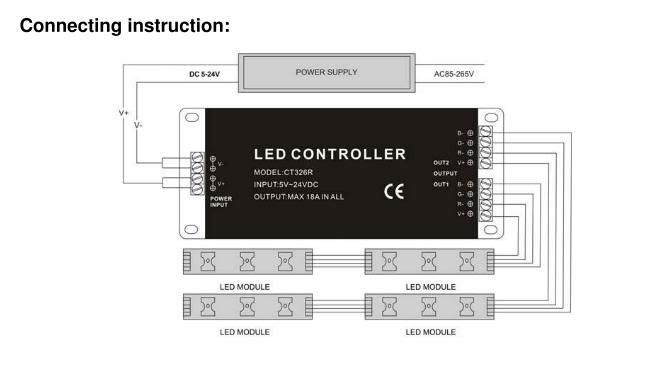

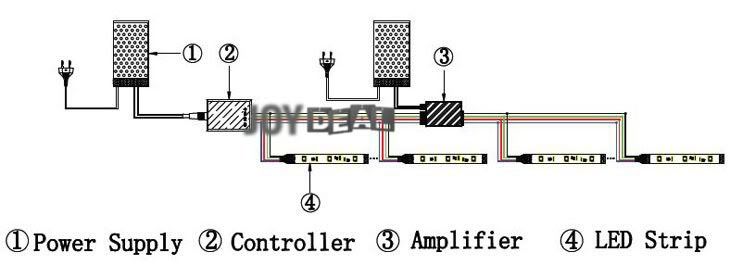

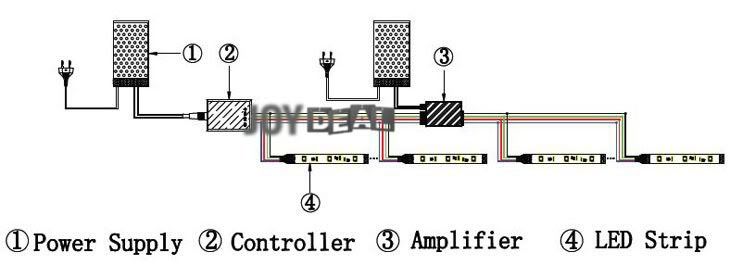

Above is a diagram of a system with power sources (Battery), one Rf controller and a amplifier and 4 led strips. Most times the amplifier will only be needed if running alot of 5M strip lighting, say more than 5 strips of 5M strips. Each RF controller will be rated for a certain number of 5m strip lights. Or a total of current allowed.

This is how I wired my boat. I installed a seperate or dedeicated fuse block with positive and negative wire from battery. Then ran positive and negative wire from the RGB Rf controller to the fuse block ground and positive lead. From there I just had to install the led strip lighting and route the 4 wire rgb wire that I bought seperate to the controller and install each wire into its proper connection point in the controller. Simple and with the fuse block, if you ever have an issue you know right where to go and it is fused properly to the size needed for the lights.

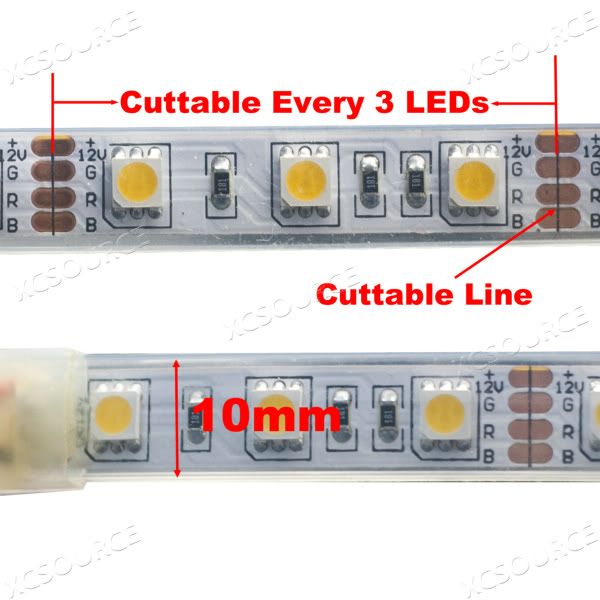

Cutting and splicing.

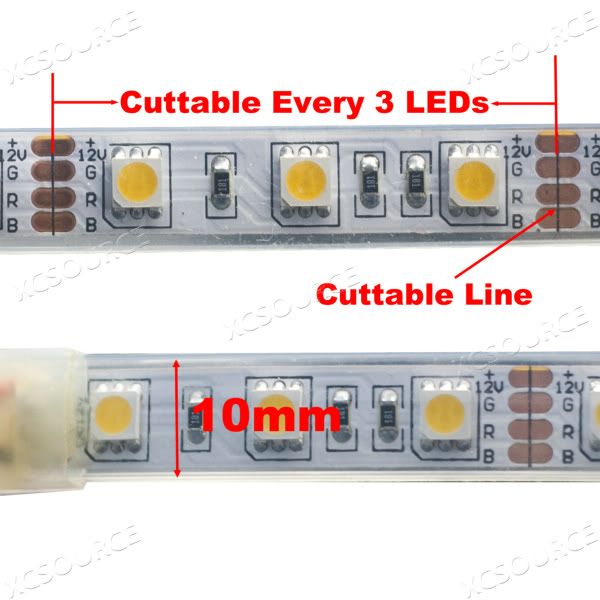

Most led strip lighting can be cut every third light. they are cleary marked and can be cut simply with a pair of scissors or dykes.

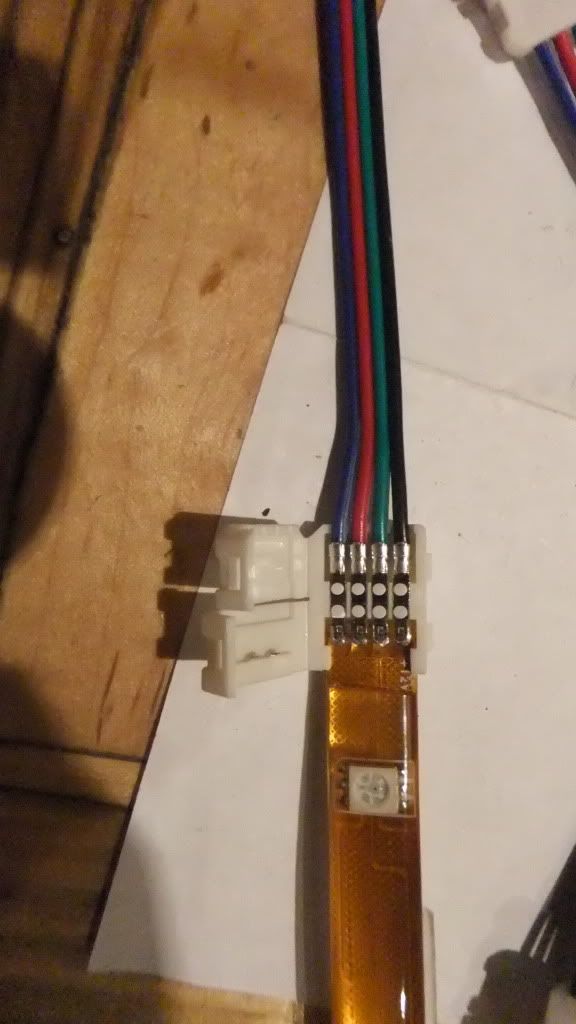

Some, but not all light strips, come with the strips already connected on one or both ends with a connector or about 10 inches or wire leads attached to wire to the boats battery or in the rgb case, to the Rf controller. When you cut your strip, you will either have to soldier new wires on the cut off section to be used in another area or connect using connectors specifically for splicing and extending strips in series.

I will try and keep this simple because it truly is simple. I personally have been installing these and learning about them for about two years now. My refurb thread shows what I have done on my boat.

Anyone can install these with a little knowledge and knowing what to order.

Not all the information given will be specific to a certain brand or manufacturer. I would say 90 percent of the led strip lights provided to us in the markets come from overseas like Honk Kong, China etc. Even if it is a usa company, in most cases they will be providing you with lights from overseas. I have no affiliation with any manufacturers or companies that sell these lights. The information I am providing is strickly from what I have learned through my experiences.

First and formost if you are using led strip lights on your boat, you need water proof lighting. Even on interior lighting, I would use waterproof lighting as humidity and other variables like salt etc can corrode the copper that the strips are made of if not protected. Will get into this more later.

Here is the first diagram I would like to share with you.

Differnent style strip lights-

Above you can see there are many different styles available. The top one is the one you "don't" want for your boat. When placing orders, make sure it says water proof or don't buy them.

The IP65 resin strips are great for outdoor use and bend well. They are offered in white, black and the copper color you see above. If bent to many times, you will break the connection in the copper,like if you try installing them more than once. These all come with self stick adhesive on the back of the strip. The self stick adhesive is a one shot deal, get it right the first time because if you pull the strip off, chances are the self stick will not last and you take the chance on crimping the light strip.

The IP65 silicone tube covered or what I like to call "sleaved" are also water proof but have no injected silicone or resin. It is simply the strip covered with a silicone sleave or tube as they call it, that protects the strip. These were the first style strips that I bought and they have lasted for two years so far installed on my boat.

The downfall of the IP65 silicone tube/sleaved is you must make sure the end caps are installed and the silicone is injected into the ends for sealing. Some of these strips come with a injection syringe and some don't. You can simply fill the end cap with silicone and slide it on the ends to seal. Most strips do not come with extra end caps, so if cutting the strip for multiple locations, you will want to purchase extra end caps for a clean a protected install.

The IP68 is epoxy resined with a silicone tube over the top of the resin incased strip. These can be used under water, they are fully protected from the elements. They are the only ones that should be used for underwater applications. If used underwater, you must make sure all connections are sealed carefully as well.

All the above are offered in different color strips, and also in one color, or "rgb" color which I will talk about more later in the thread.

Different light numbers per strip and the sizes of those lights.

As seen above, there are two different size lights ofered in these strips. When ordering, make sure you get what you want.

The SMD 3528 LED strip light has smaller lights than the SMD 5050 strip lights. They are also cheaper to buy if the number of lights per meter of light strip is the same. Will talk more on this down in the thread.

The SMD 5050 LED strip light has larger lights than the SMD 3528 strip lights. The 5050 lights are individually brighter than the 3528 LED strip lights individually are. The 5050 lights can be up to 3 times brighter per light than the 3528 sized lights.

Now, the reason I said individually is, both the SMD 3528 LED strip and the 5050 Led strip, is offered with either 30 lights per meter or 60 lights per meter. The more lights you have the smoother the light will be and less hot spots you will have after installation.

When I say hot spots, with the smaller led lights at 30 lights per meter will give you good lighting, but they are smaller lights and can give you dull or bright spots where the light isn't filled between lights on the strip. And as said before are not as bright as the 5050 lights.

With the 60 lights per meter, you will have less hot spots and more light output per strip. Both the 3528 and the 5050 are offered with the 60 lights per meter but are harder to find online and are more expensive, but still reasonable.

Not to confuse anyone, but a 60 light per meter 3528 strip will probably be better than a 5050 light strip with only 30 lights per meter or atleast just as good.

To recap, the less lights (30 per meter) and the less the number in front of the light strip (3528) the least expensive they will be to purchase but are not the best. These lights are the most economical and will give the average person a thrill once installed. For led inthusiast like myself, I want the best light available and the best look. So future purchases will all be IP68, 5050 with 60 lights per meter.

Static one color or RGB light strips. .

This is where things get interesting. Each light strip wether it be 3528 or 5050 is offered in a one color or multi-color (rgb).

The one color light strip is simple. If you only want one color like red, white, blue, purple, green, etc, then you order that particular color when ordering your light strips. These light strips can simply be controlled by an on/off switch. I would suggest a dimmer atleast if you buy one color. Actually I would suggest you spend a little more mula and get some RGB lights so you always have the choice of different colors.

Remember red is the only color good for underway if you plan on using these while on the move. Red does not effect your night vision.

RGB light strip means (RED,GREEN,BLUE), with these lights you can pretty much turn any color you chose depending on the RF controller that you buy to go along with them.

The RGB light strips must be controlled by a Rf controller with IR remote controller. These controllers come as a package deal or can be bought seperate from the rgb lights strips.

All RGB, RF controllers, and there related IR remotes are not created equal. Some will turn your lights 3 different colors, some will turn them 7 different colors, some will turn your light strips like 20 different colors. I like having the most options available per dollars spent.

RGB RF controllers offer different selection of control. Static for each color, blinking, fade, dimming etc etc etc. Different controllers will have more or less control options depending on what you select to purchase.

RGB controllers are also all different in the way they except your wiring for those rgb lights. The controller and remote I prefer at this time is this one. I have a couple others and this one is the easest to install wires into from the strip lights and battery.

Many of you have seen the back of a home stereo system where your speaker wires just get slid into a connector that has either a spring loaded arm that holds the wire connection tight or a screw type that tightens down on the stripped wire. This controller is just like the latter, it has a screw you loosen, stick in the wire, and tighten the screw down on the wire installed. The controller is marked r,g, b and V+. These mark the color coded wire to the proper input to the RF controller and the hot and negative inputs are also marked.

Wiring your system.

I won't get into to many specifics here because it will be up to the individual boat owner on how they want the lighting system wired into there boat.

Above is a diagram of a system with power sources (Battery), one Rf controller and a amplifier and 4 led strips. Most times the amplifier will only be needed if running alot of 5M strip lighting, say more than 5 strips of 5M strips. Each RF controller will be rated for a certain number of 5m strip lights. Or a total of current allowed.

This is how I wired my boat. I installed a seperate or dedeicated fuse block with positive and negative wire from battery. Then ran positive and negative wire from the RGB Rf controller to the fuse block ground and positive lead. From there I just had to install the led strip lighting and route the 4 wire rgb wire that I bought seperate to the controller and install each wire into its proper connection point in the controller. Simple and with the fuse block, if you ever have an issue you know right where to go and it is fused properly to the size needed for the lights.

Cutting and splicing.

Most led strip lighting can be cut every third light. they are cleary marked and can be cut simply with a pair of scissors or dykes.

Some, but not all light strips, come with the strips already connected on one or both ends with a connector or about 10 inches or wire leads attached to wire to the boats battery or in the rgb case, to the Rf controller. When you cut your strip, you will either have to soldier new wires on the cut off section to be used in another area or connect using connectors specifically for splicing and extending strips in series.

Last edited: