I'm back at it. I seem to go in waves of productivity and then let it sit for a bit. I had a week off of work so I decided to get back out there and make some progress. It's about time, since my last post was in October. I headed down to the shop and found a nasty surprise.

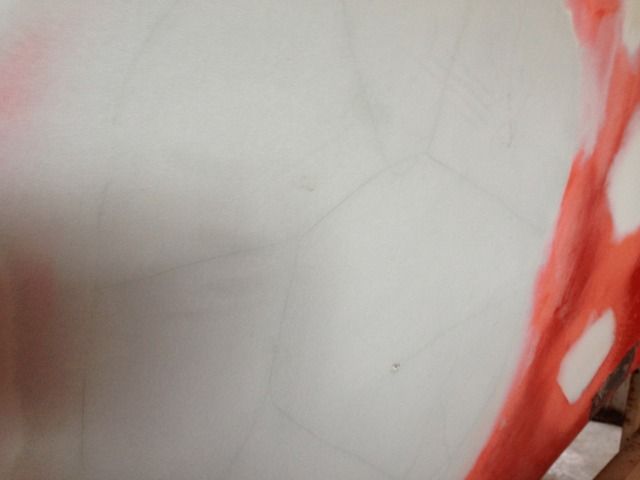

It appears that a lot of the repair that I farmed out to that other shop has cracked over the winter. It looks like where the filler was super thick, it contracted when the temperature changed.

Here's another place that's cracking out. My two thoughts are, I'm glad it happened before I painted the boat, and I don't think I'm going to use that shop again.

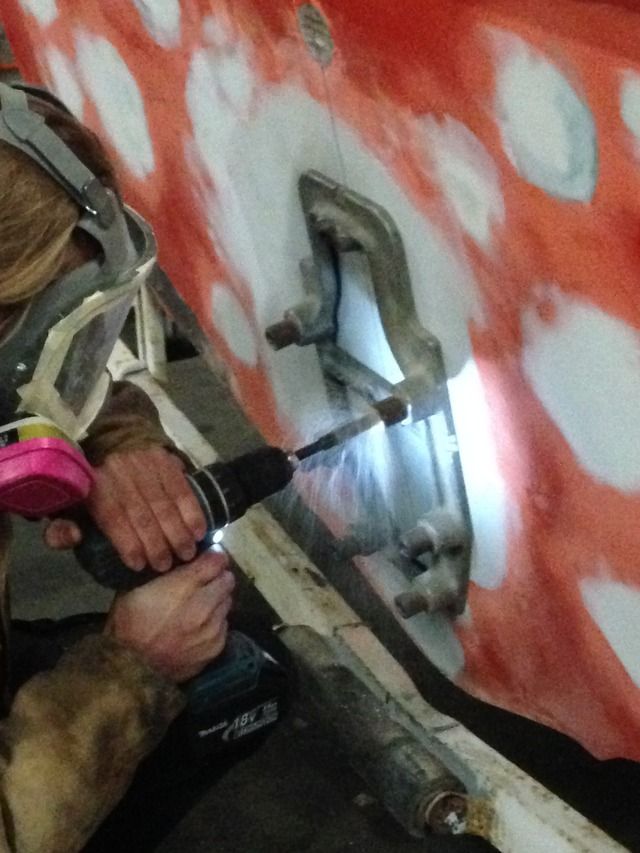

I drilled out my reference hole for the X-dimension and a chunk of filler cracked out around it. Obviously I'm going to have to re-do this work. I could take it back and make them fix it. I don't know, I'm going to have to decide what I want to do. As for now, the next task that I was planning on doing, was cutting the keyhole in the transom. I paused for a moment to consider whether or not I wanted to re-do the cracked area first, but I decided to go ahead and cut the keyhole because after all the work I've done, I'm probably going to have to do some tweaking to the transom anyway to get the thickness between 2 and 2 1/4 inches as per Mercruiser's specs. I can just do it all at the same time. I've looked around for the drill jig that Mercruiser makes to cut the correct hole, and the cheapest I can find it is $200. That's pretty expensive for a tool I'm only going to use once, so I started checking around locally to see if anyone could help me. I found a shop here in Salt Lake called Davidson Marine. Bastian over there was super cool guy and quoted me $50 to drill the bolt holes and cut the center out.

The centerline is re-drawn.

The jig is attached to the transom.