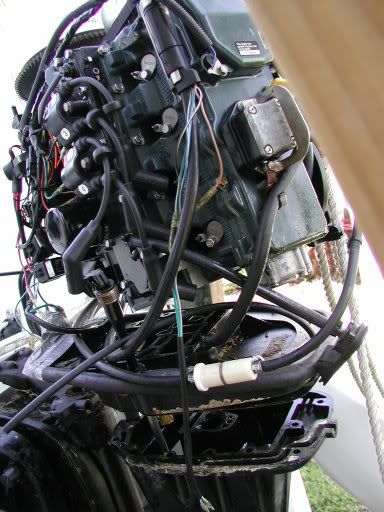

Hi folks, I just joined here as I heard this is the place to go with outboard problems.<br /><br />I have a 2000 Mercury BigFoot 50HP 4-stroke (before EFI) Serial # 0T071106 and I have been having overheat problems for several months now. The motor ran flawlessly for years before that and asides from the overheat problem, it still runs well now.<br /><br />When it first started overheating, I did the obvious and pulled the lower unit and put a new impellor in. It was the original impellor that came out, looked as good as the new one. In the 5 times I have dropped the lower unit since then, I have replaced all the water pump parts including the connector hose and water pump body. I have tried 2 brand new impellors.<br /><br />After the problem persisted, I replaced the thermostat. Before putting in the new one, I put it in some hot water with a thermometer and verified that it was opening at the right temperature. Both the old and the new thermostats work perfectly.<br /><br />I have also taken off the water jacket cover and everything in there was clean. I forced compressed air and pressurized water in through all the openings I observed and did not find any problem. Except that a small amount of water comes out of the copper tube where the water pump connects too. I blew high pressure water backwards through the system and got what appeared to be a partial clog out. I never saw anything come out per se, but now the water was flowing much better and I no longer overheat on the flusher, but it still does not flow as well as I think it should and it still does overheat under load. when I backflush it with the lower unit off, most water comes out around the exhaust pipe. Much less comes out of the copper input tube, it is more than a trickle but less than the gusher I would expect out of the tube (must be about half inch in diameter, maybe 5/8).<br /><br />Also, when I force water up the copper input tube, there seems to be a lot more backpressure than I would expect. With full house pressure and holding a hose onto it very tightly, I can force water to go through the system, but I don't think I should have to hold the hose so tightly. When I run the motor with the ear muff flusher, I get a much better stream than with the motor in the water. The water dribbles out even with the new water pump. The flusher appears to mask my problem.<br /><br />My best guess at this point is that I have a partially obstructed water tube, or the area where the water tube connects to the powerhead. So far, I have only tried to ream it with weed wacker line but that is not very rigid. My question is whether I should drop the lower unit one more time and see if I can ream the water tube with something more rigid, like a coat hanger for example. If that doesn't solve it, seems like the powerhead may have to come off.<br /><br />Any ideas or advice out there?<br /><br />You can see even more details of this problem at the boat BB where I have been originally posting about it and folks have been trying to help.<br /> here is the web page link <br /><br />Thanks in advance for any comments.

- Shop

-

Main Menu Find The Right Fit

-

-

Slide Anchor Box Anchors Shop Now

-

Back Fishing

-

View All

- Fishing Rods

- Fishing Reels

- Fishing Rod & Reel Combos

- Fishing Tools & Tackle Boxes

- Fishing Line

- Fly Fishing

- Fishing Bait & Fishing Lures

- Fishing Rod Holders & Storage Racks

- Fish Finders, Sounders & Sonar

- Trolling Motors

- Fishing Nets

- Fishing Downriggers & Acessories

- Fishing Outriggers & Acessories

- Fishing Kayaks

- Fish Cleaning Tables

-

-

Minn Kota Riptide Terrova 80 Trolling Motor w/i-Pilot & Bluetooth Shop Trolling Motors

-

SportsStuff Great Big Marble Shop Tubes

-

Big Jon Honda 5hp Outboard Shop Outboards

-

Lexington High Back Reclining Helm Seat Shop Helm Seats

-

Kuuma Stow n Go BBQ Shop Now

-

Slide Anchor Box Anchors Shop Now

-

Back Electrical

-

View All

- Boat Wiring & Cable

- Marine Batteries & Accessories

- Marine DC Power Plugs & Sockets

- Marine Electrical Meters

- Boat Lights

- Marine Electrical Panels & Circuit Breakers

- Power Packs & Jump Starters

- Marine Solar Power Accessories

- Marine Electrical Terminals

- Marine Fuse Blocks & Terminal Blocks

- Marine Switches

- Shore Power & AC Distribution

-

-

ProMariner ProNautic Battery Charger Shop Marine Battery Chargers

-

Lowrance Hook2-4 GPS Bullet Skimmer Shop GPS Chartplotter and Fish Finder Combo

-

Boston Whaler, 1972-1993, Boat Gel Coat - Spectrum Color Find your boats Gel Coat Match

-

Rule 1500 GPH Automatic Bilge Pump Shop Bilge Pumps

-

Back Trailering

-

SeaSense Trailer Winch Shop Trailer Winches

-

Seadog Stainless Steel Cup Holder Shop Drink Holders

-

Slide Anchor Box Anchors Shop Now

-

- Boats for Sale

- Community

-