RogersJetboat454

Commander

- Joined

- Jul 9, 2010

- Messages

- 2,964

Suppose I will add another thread about the humble little Fleetwin.

This is my cousin's motor, and in fact the first motor I got to operate solo some 15+ years ago. I have fond memories of taking her out to explore the lake (in our general area of course), as well as my cousins I'm sure. Well one of my cousins is a proud papa, and his boy is getting near the age of being able to take the tiller for the first time. The old Evinrude has been sitting dormant for the past 7 or 8 years, and I think it's time to wake her up and get her ready. I owe it to her!

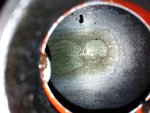

The last year she was in service, I had replaced the leg with a donor from a Johnson. The old leg had cracks, leaked, and didn't have a great working reverse. Plus it eventually locked up from moisture intrusion. So the new leg was put together, along with a impeller kit. But for some reason it dribbled oil. This will be something I will be addressing this time around. The other thing I also noticed was the power wasn't all that great (maybe my expectations were a bit high). So I plan on cleaning up the carb, checking over the ignition system, and taking a peak inside the cylinders.

I took it apart today with some free time at work.

This is my cousin's motor, and in fact the first motor I got to operate solo some 15+ years ago. I have fond memories of taking her out to explore the lake (in our general area of course), as well as my cousins I'm sure. Well one of my cousins is a proud papa, and his boy is getting near the age of being able to take the tiller for the first time. The old Evinrude has been sitting dormant for the past 7 or 8 years, and I think it's time to wake her up and get her ready. I owe it to her!

The last year she was in service, I had replaced the leg with a donor from a Johnson. The old leg had cracks, leaked, and didn't have a great working reverse. Plus it eventually locked up from moisture intrusion. So the new leg was put together, along with a impeller kit. But for some reason it dribbled oil. This will be something I will be addressing this time around. The other thing I also noticed was the power wasn't all that great (maybe my expectations were a bit high). So I plan on cleaning up the carb, checking over the ignition system, and taking a peak inside the cylinders.

I took it apart today with some free time at work.