Roberthill

Petty Officer 1st Class

- Joined

- Dec 3, 2012

- Messages

- 317

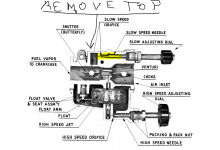

Adjusted carb to run wide open but when it's on slow running have to adjust high and low jets about half a turn richer and when running slow have to adjust jets half a turn leaner . Can someone please point me into what to check for this?