ChapBoater

Seaman

- Joined

- Jun 1, 2014

- Messages

- 51

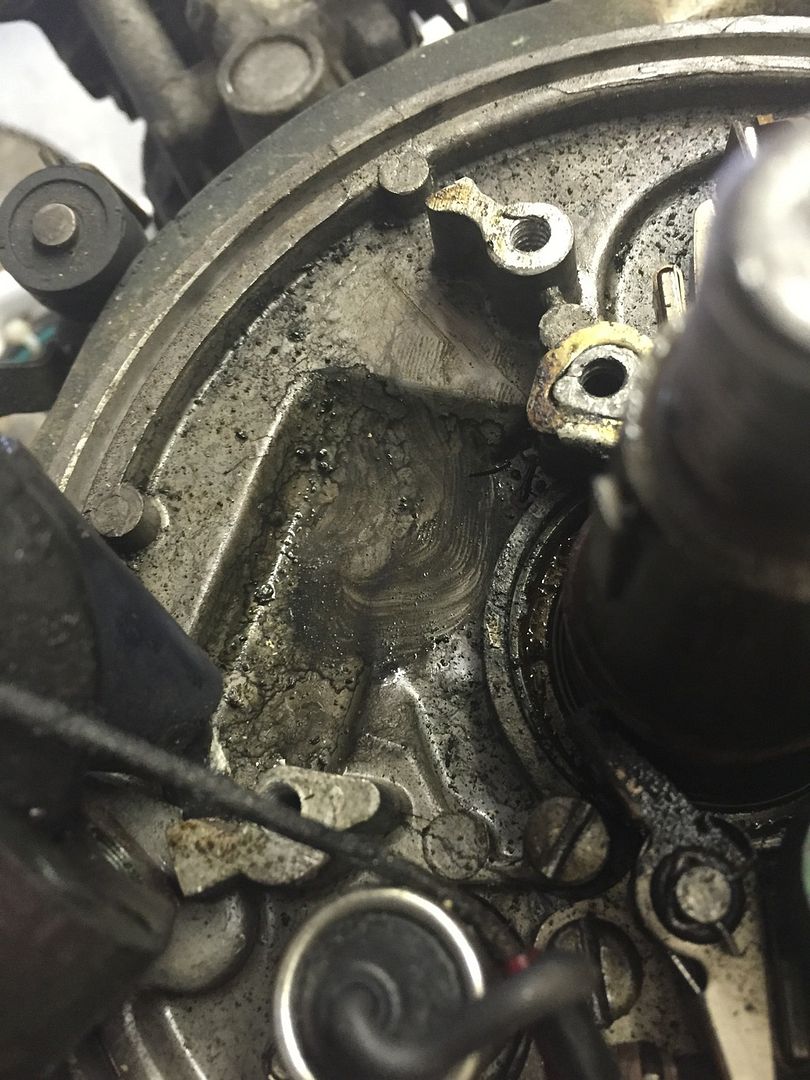

I just recently picked up a 1963 Sea King that needs a little bit of love. Its been parked under a tree for the last 6 months or so and neglected the last 5 years from what I have been told. I picked the boat up last Saturday and started work as soon as I got home. I checked compression and came in at 85psi per hole on a 1962 Johnson 28hp. The carb came off and got a good cleaning and surprisingly was in very good shape, a rebuild kit went in and it went back on. I did a quick test fire to see what would happen, it turned over immediately (that was a sigh of relief). The previous owner had attempted to put in an ignition and in doing so, ripped out the stop button and put in a start button, and took off one of the wires coming from the magneto. Thanks to iboats and a very helpful user here I was able to figure out what should be there and what was missing. I'm not sure what would cause someone to want to do that but I will be fixing all that down the road.

My main focus is the stringers, deck and interior first. I ripped out the existing deck and the thousands of leaves, bugs and cockroaches. Once I got that out I got to the foam which was in good shape and cleaned up very well. All the stringers were in good shape and required very minimal work. I picked up some 3/4 plywood for the new deck and cut it all to size and test fitted. It will be coming back out shortly to get some resin and mat. This is my first attempt with fiberglassing so any tips will be appreciated! This is where I stand right now, I have the plans for the interior drawn up and all measurements done with a material list made for everything I will need to get it done.

The one area I haven't figured out how to build yet is going to be the bench seat that I am going to put up front. Anyone have plans or directions on how to build a sturdy bench seat?

Picking up the boat from its leafy grave

The drive home cleared out a good portion of the leaves that we're on top of the deck.

Stringers and foam once the deck was removed

Foam and stringers removed, took a lot of water and air to get all the leaves and dirt to one area so I could clean it up. Biggest cockroaches I've ever seen in my life

Hull, foam and stringers cleaned up and put back in. First piece of deck is cut and fitted. I took the opportunity while everything was out to paint the interior sides and aluminum trim around the boat. Looks 1000x better with just this one small improvement

Forward deck fitted in place, still have to figure out what I am going to do deck wise underneath the front section, any ideas?

Trying to decide if I want the patina look and just have it cleared or if I am going to have the whole boat painted

I love the original wrap around tall windshield that is on these but I realize it will be next to impossible to find out, anyone have any tips on how/who to build a custom windshield?

My main focus is the stringers, deck and interior first. I ripped out the existing deck and the thousands of leaves, bugs and cockroaches. Once I got that out I got to the foam which was in good shape and cleaned up very well. All the stringers were in good shape and required very minimal work. I picked up some 3/4 plywood for the new deck and cut it all to size and test fitted. It will be coming back out shortly to get some resin and mat. This is my first attempt with fiberglassing so any tips will be appreciated! This is where I stand right now, I have the plans for the interior drawn up and all measurements done with a material list made for everything I will need to get it done.

The one area I haven't figured out how to build yet is going to be the bench seat that I am going to put up front. Anyone have plans or directions on how to build a sturdy bench seat?

Picking up the boat from its leafy grave

The drive home cleared out a good portion of the leaves that we're on top of the deck.

Stringers and foam once the deck was removed

Foam and stringers removed, took a lot of water and air to get all the leaves and dirt to one area so I could clean it up. Biggest cockroaches I've ever seen in my life

Hull, foam and stringers cleaned up and put back in. First piece of deck is cut and fitted. I took the opportunity while everything was out to paint the interior sides and aluminum trim around the boat. Looks 1000x better with just this one small improvement

Forward deck fitted in place, still have to figure out what I am going to do deck wise underneath the front section, any ideas?

Trying to decide if I want the patina look and just have it cleared or if I am going to have the whole boat painted

I love the original wrap around tall windshield that is on these but I realize it will be next to impossible to find out, anyone have any tips on how/who to build a custom windshield?