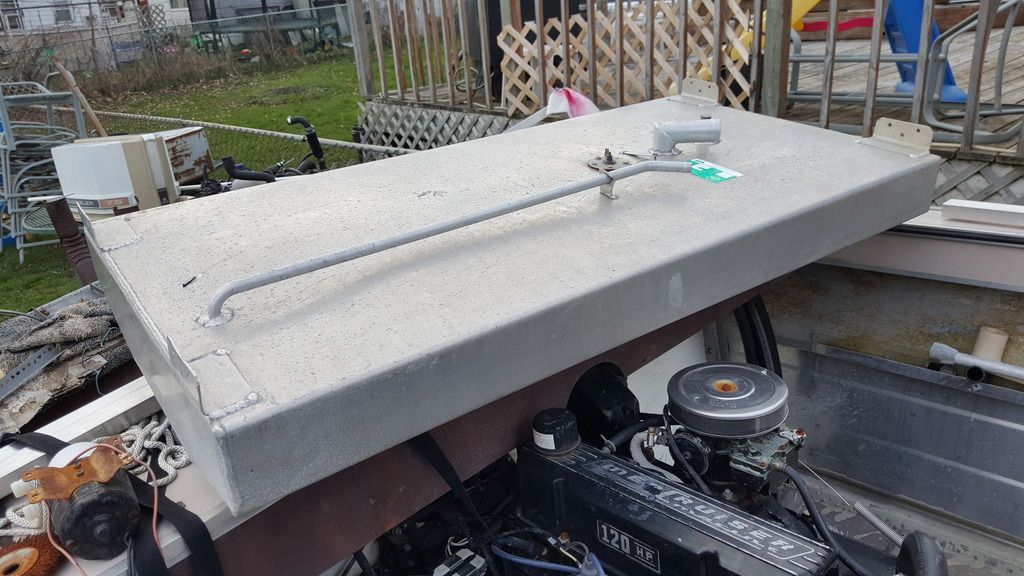

Hello Starmada. I have a mostly gutted 18 foot Holiday V I/O in my yard that I really want to get into the water by the end of the season. My plan is to replace the above deck Mirax steel fuel tank with a below deck 26 gallon aluminum model. As all of you whom have removed the deck knows, there isn't a whole lot of room down there, I toyed with the idea of leaving the deck height the same and building a storage platform and live well over the fuel tank in order to prevent it from being a dangerous tripping hazard. But when I started mocking it up I didn't like the way it looked or the lost walking space on the deck and it would have made working on the front of the motor a real pain. So I decided I would raise the deck.

Initially I purchased rectangular aluminum tubing that was 1" X 1.5" 0.125 thick. It was a pain and I gave up on that project. I will re-task the tubing for other things. I called around metal fabricators and am going to have new stringers formed, The original material is 5052 aluminum 0.065" thickness. The question though is whether I should stay with the same thickness. Initially I was quoted on 0.125" thickness but I have concerns about the angles not holding up over time. Should I stick with the 0.065" or should I step up one thickness to 0.080"? In addition to the main stringers I'm also having stringers fabricated for the end of the ribs to support the outer edges of the deck.

Now for the deck. The original deck was 1/2" I would like to replace it with 3/4" to add stiffness but I am not certain if there is enough benefit to justify increasing the deck weight by 50%.

The thoughts of anyone that has done something similar or considered it would be greatly appreciated. Thank you in advance for your input.

Initially I purchased rectangular aluminum tubing that was 1" X 1.5" 0.125 thick. It was a pain and I gave up on that project. I will re-task the tubing for other things. I called around metal fabricators and am going to have new stringers formed, The original material is 5052 aluminum 0.065" thickness. The question though is whether I should stay with the same thickness. Initially I was quoted on 0.125" thickness but I have concerns about the angles not holding up over time. Should I stick with the 0.065" or should I step up one thickness to 0.080"? In addition to the main stringers I'm also having stringers fabricated for the end of the ribs to support the outer edges of the deck.

Now for the deck. The original deck was 1/2" I would like to replace it with 3/4" to add stiffness but I am not certain if there is enough benefit to justify increasing the deck weight by 50%.

The thoughts of anyone that has done something similar or considered it would be greatly appreciated. Thank you in advance for your input.