Cdubb2010

Petty Officer 3rd Class

- Joined

- Apr 22, 2014

- Messages

- 79

Alright, you folks here have helped me out many times before let's see if you can again.

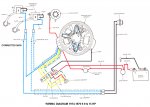

I picked this motor up in a horse trade deal last week. Guy I got it from moonlights as a marine mechanic and it was put on the back burner. He put one new coil pack on it, new fuel line and carb got rebuilt but it has no spark. He thought it was in the kill switch ( this one is mounted by the choke not on the tiller as some I've seen). We pressed in the kill switch and pulled it over and got no spark, so we pulled the switch and tested it with a multi meter and the switch is indeed bad. So I linked the three wires going to it together and I still have no spark. Is there a fault in how I tested the kill switch theory? So I moved on amd popped the flywheel off to look in there, nothing seemed out of the ordinary until we looked at the contact set (so the parts store has them listed as). They are supposed to be at .020 and one side is touching the other one is close to being right but is too far out. Would this cause no spark? I'm used to working on cars, this is forgin to me to a point. The attached photo shows the side that is touch on one side of the arm. Also if some one has a wiring diagram they can post that would be very helpful or even a link to a service manual.

Regards

I picked this motor up in a horse trade deal last week. Guy I got it from moonlights as a marine mechanic and it was put on the back burner. He put one new coil pack on it, new fuel line and carb got rebuilt but it has no spark. He thought it was in the kill switch ( this one is mounted by the choke not on the tiller as some I've seen). We pressed in the kill switch and pulled it over and got no spark, so we pulled the switch and tested it with a multi meter and the switch is indeed bad. So I linked the three wires going to it together and I still have no spark. Is there a fault in how I tested the kill switch theory? So I moved on amd popped the flywheel off to look in there, nothing seemed out of the ordinary until we looked at the contact set (so the parts store has them listed as). They are supposed to be at .020 and one side is touching the other one is close to being right but is too far out. Would this cause no spark? I'm used to working on cars, this is forgin to me to a point. The attached photo shows the side that is touch on one side of the arm. Also if some one has a wiring diagram they can post that would be very helpful or even a link to a service manual.

Regards