StarTed

Senior Chief Petty Officer

- Joined

- Jul 14, 2015

- Messages

- 694

I bought a 1976 75 hp Evinrude that the PO said needed a new head gasket since there was some light colored foamy stuff on the middle spark plug. This was last fall and I've been sitting on it ever since.

When I pulled the plugs I noticed a trace of tan colored stuff on the center cylinder plug that indicated to me that the PO was correct in that regard.

A compression check using an available deep cycle non starting battery showed all cylinders the same with a little over 100 psi.

I pulled the head anyway and found that the head gasket looked good with no evidence of leakage into any cylinder. However, there was no thermostat installed when I pulled its cover.

Could the moisture have been caused by operating it at a low temperature?

Could the middle cylinder not be firing properly and causing the moisture?

Are there any other causes that could be causing the moisture?

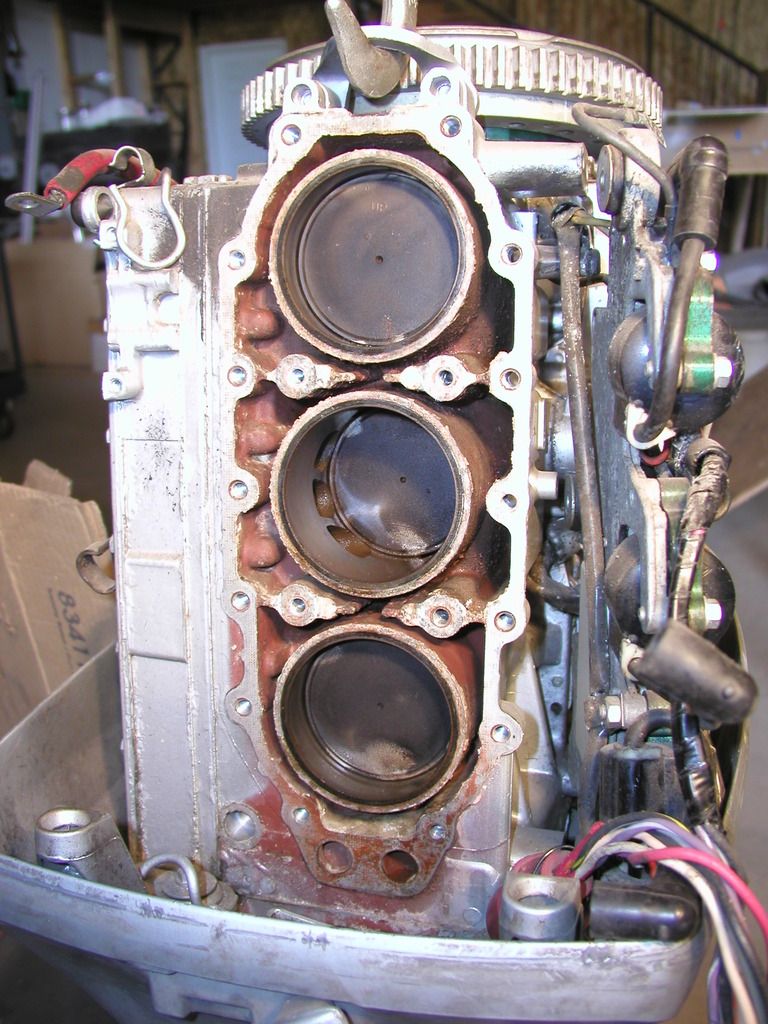

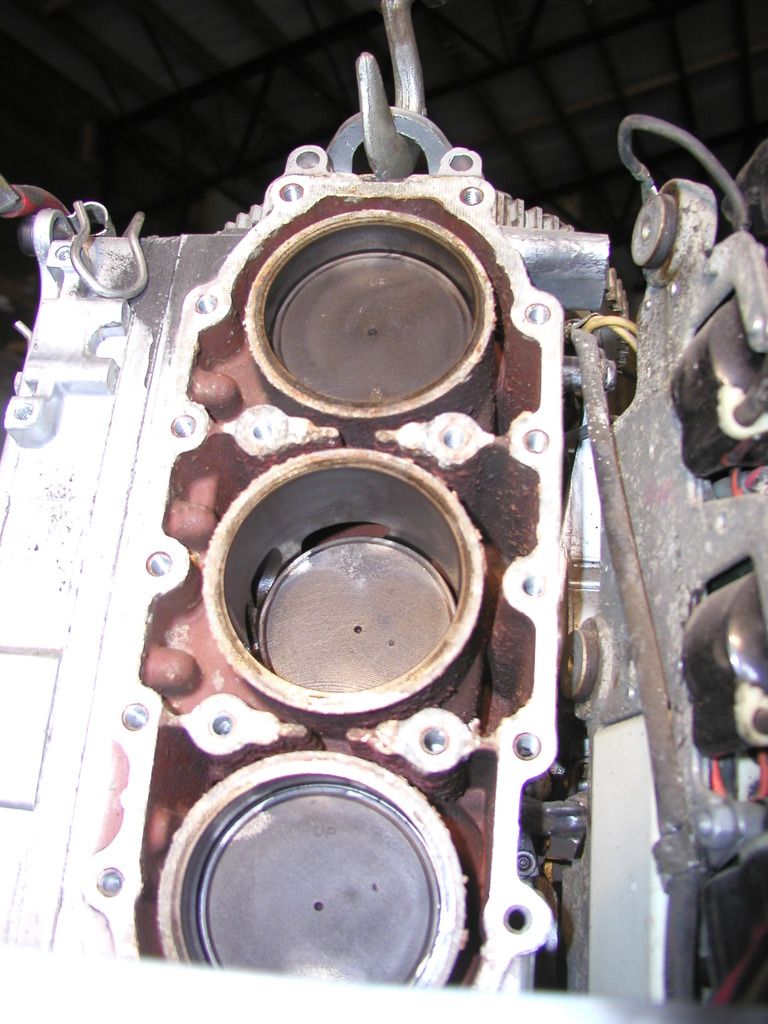

I don't think there was much moisture getting in but that information is no longer available to me. Here are some pictures.

Head with gasket just lying on it.

Head with gasket flipped over.

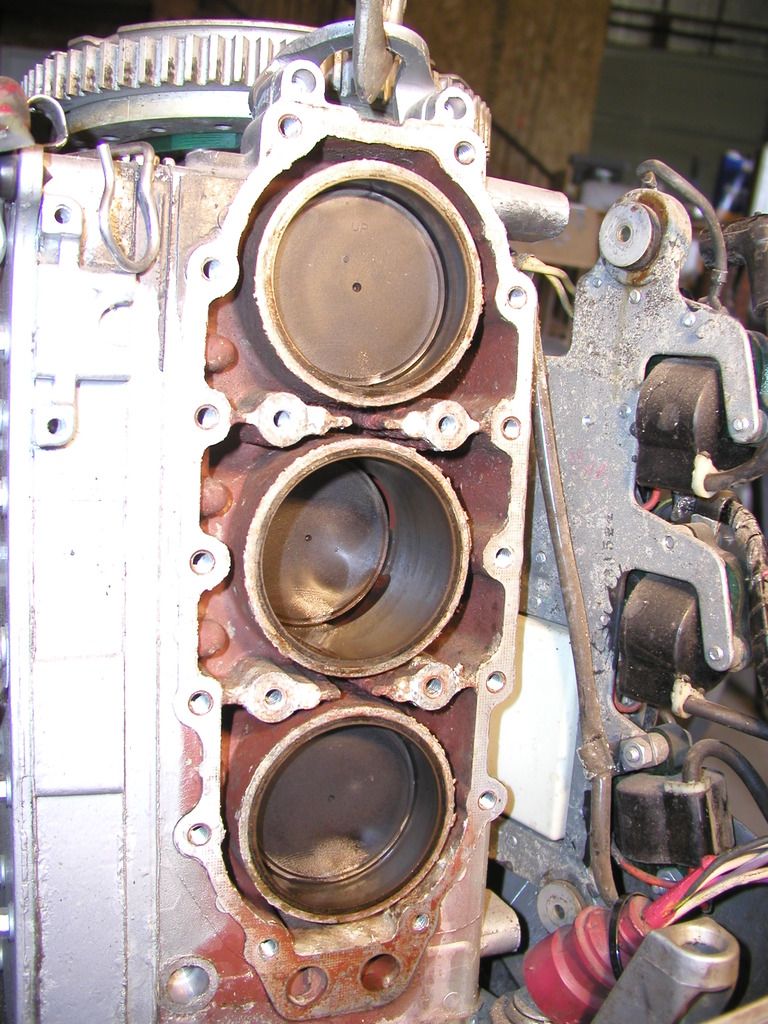

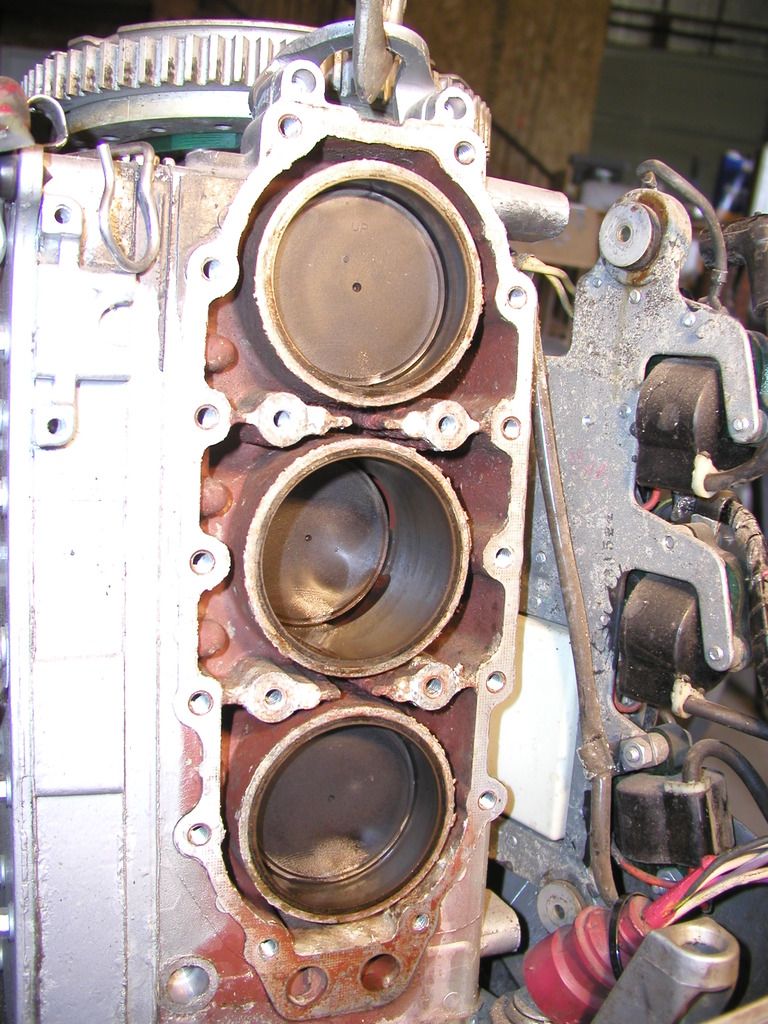

View of cylinders

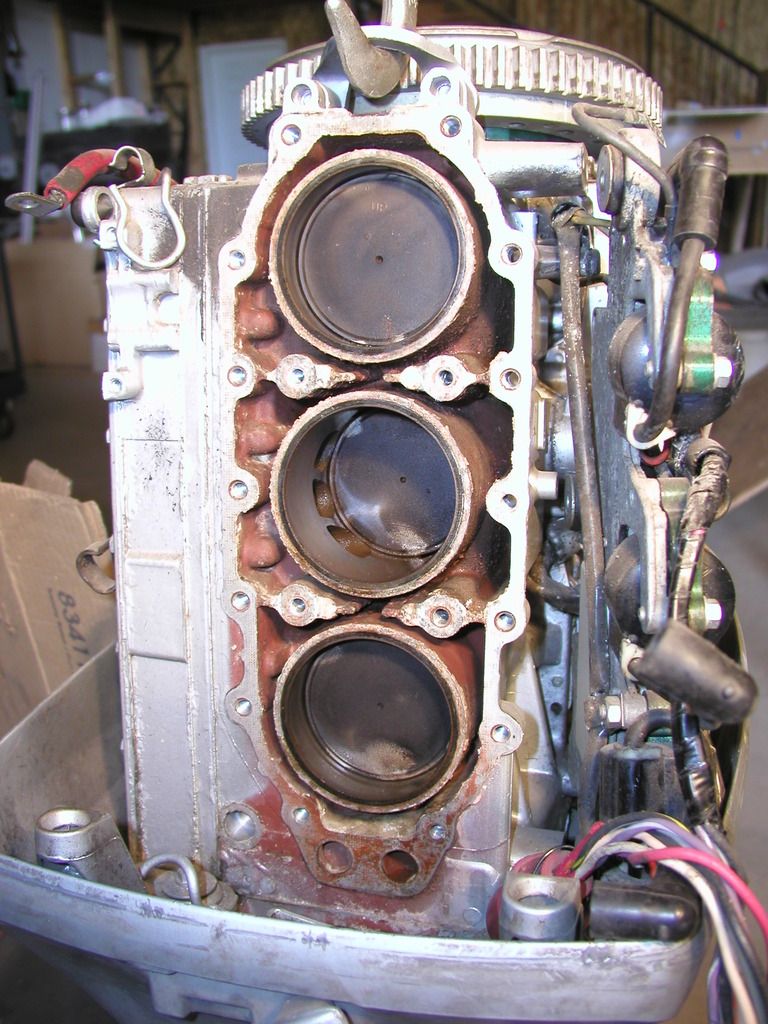

Another view of cylinders

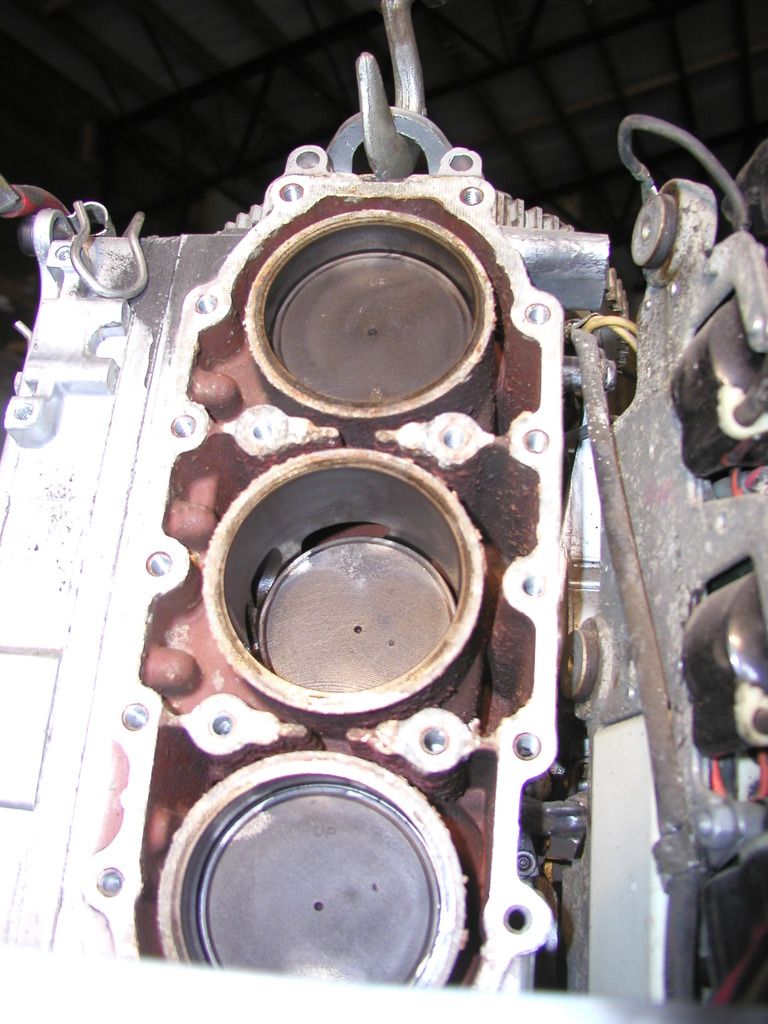

Low angle view of cylinders

I don't see anything that I would think would have been the problem.

Next steps?

I'm planning to replace the head gasket, thermostat kit, impeller, fuel pump kit, carburetors kits and spark plugs. Any other suggestions?

By the way, it has a jet pump on it so testing it in a barrel is out.

When I pulled the plugs I noticed a trace of tan colored stuff on the center cylinder plug that indicated to me that the PO was correct in that regard.

A compression check using an available deep cycle non starting battery showed all cylinders the same with a little over 100 psi.

I pulled the head anyway and found that the head gasket looked good with no evidence of leakage into any cylinder. However, there was no thermostat installed when I pulled its cover.

Could the moisture have been caused by operating it at a low temperature?

Could the middle cylinder not be firing properly and causing the moisture?

Are there any other causes that could be causing the moisture?

I don't think there was much moisture getting in but that information is no longer available to me. Here are some pictures.

Head with gasket just lying on it.

Head with gasket flipped over.

View of cylinders

Another view of cylinders

Low angle view of cylinders

I don't see anything that I would think would have been the problem.

Next steps?

I'm planning to replace the head gasket, thermostat kit, impeller, fuel pump kit, carburetors kits and spark plugs. Any other suggestions?

By the way, it has a jet pump on it so testing it in a barrel is out.