Hey guys and gals. This one has been a long time in the making, so hopefully you like it! I'd love to hear your feedback, suggestions for improvements, things I screwed up.

The basics:

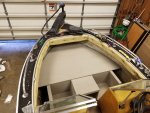

I got permission last spring to go buy a "new" fishing boat, and we wanted to spend about $4,000. The only real guidelines I had were: It needed to fit in the garage, and it needed to have a full windscreen. Beyond that, it just needed to float and move.

Long story short, I figured out that there wasn't a lot out there that met those criteria. Lots of $2000 projects and $6000 well-kept boats. Me, being as cheap as I am went the $2000 route, thinking I could put a bit of money into it that spring, fish in it through the summer, then spend some time in the winter doing it right. As you'll see below, that plan didn't work out. Over the course of last spring/early summer, I completely re-did the interior. Then this spring/summer I re-did the outside and the trailer.

"Before" pics are attached here.

Enjoy the read!

(I'm going to break this up into a couple of different posts, hope that's cool with everyone!)

The basics:

I got permission last spring to go buy a "new" fishing boat, and we wanted to spend about $4,000. The only real guidelines I had were: It needed to fit in the garage, and it needed to have a full windscreen. Beyond that, it just needed to float and move.

Long story short, I figured out that there wasn't a lot out there that met those criteria. Lots of $2000 projects and $6000 well-kept boats. Me, being as cheap as I am went the $2000 route, thinking I could put a bit of money into it that spring, fish in it through the summer, then spend some time in the winter doing it right. As you'll see below, that plan didn't work out. Over the course of last spring/early summer, I completely re-did the interior. Then this spring/summer I re-did the outside and the trailer.

"Before" pics are attached here.

Enjoy the read!

(I'm going to break this up into a couple of different posts, hope that's cool with everyone!)

Attachments

Last edited by a moderator: