Hi All,

Main issue #1 :

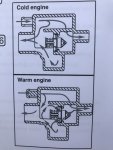

Cracked 3 exhaust manifolds, thinking bad casting work / valve lash heating up issues, etc and now found out, stupidly, that in thermostat housing 3850764 there is NO bypass hole to let cold / mixed water into the exhaust manifold as supposed to the design drawings. It isn't there, the actual casting is different from the design dwg's and an original VP supply on the engine, it simply can't even host this bypass. And yes, the manifold got hot but what did I know (as reference). Solved this now by putting a Merc housing on the engine with the VP therm. stat. Now my manifold keeps nicely on hand touching temp. Anyone known to this issue with that thermostat housing of VP ???, you know what a cracked manifold does to your engine ... Secondly, the temp. sensor doesn't pick this thing up on a 3.0L so that missing bypass is an engine killer potentially. Luckily I listen now better and check my gaskets always after starting and avoided serious water ingestion .... after learning it the hard way. Anyhow, too late when your gaskets leak.

Please, see also some pictures I added to get a visual on this.

Sub issue #2 :

Why does a 3.0GSMBYMCE flow raw water from the thermstat hsg to the riser directly ??? Is this to create a flow vacuum (for manifold suction) a/o acting as a pressure release function ? It seems not to be effective to stabilize the temperature house-holding at all and avoids picking up heat issues. Yeah, it avoids blowing your hoses by steam flashing. Merc. doesn't provide this (connection on the thermstat hsg to riser). So we plugged the riser hose. The riser, obviously gets now hotter and logically doesn't get warmer then the manifold now as it now only gets water from the manifold and keeps hand warm and thus slightly lower now then the manifold. It fits now to the overall thermal house-holding.The exhaust water temp out the drive is now higher, meaning it takes more heat out the system then it did. I was a bit afraid flow through the manifold would be too high to take heat out, actually it takes out better now. I guess it's about 60 degr. Celcius or a bit higher. In the former condition hardly water was entering the manifold, we investigated this (I guess no vacuum suction flow over the open thermstat from the bypass water flow and it was simply missing the volume from the bypass ...) The sensor temp. is at 75-80 degrees Celsius so the engine block itself keeps "as it was" on operating temp. as well, measured sensor temp according spec.

Thus with the Merc housing the manifold gets cold/mixed temp. water and feels okay, the riser is about the same temp. now. So the current design using the Merc approach seems to be okay. But perhaps someone of you can tell me if the riser needs that particular and basically direct raw water connection or any other risk with this?

Sub issue #3 :

The third time a cracked manifold, started searching barn finds this time (wife ain't enjoining my hobby anymore and eBay became to luxury for me , ...) and got myself an model but original VP manifold with the only difference that I cannot feed the PCV tube in it. Merc is entering the flame arrestor, can I tap this tube in the tube going from the valve cover to the flame arrestor (T-connector) instead, tap in directly or just leave it open (not favored) ? Also, my current Holley 2300 carb doesn't provide entry although I have one that has a hose tule on the baseplate plugged off).

, ...) and got myself an model but original VP manifold with the only difference that I cannot feed the PCV tube in it. Merc is entering the flame arrestor, can I tap this tube in the tube going from the valve cover to the flame arrestor (T-connector) instead, tap in directly or just leave it open (not favored) ? Also, my current Holley 2300 carb doesn't provide entry although I have one that has a hose tule on the baseplate plugged off).

Observation #4 :

I noticed the Merc use lower temp. thermstats. although the re-circulation hose felt okay about 80-85 degrees Celsius the sensor gave a lower value to the gauge, still after (full ?) opening. So we installed the VP thermstat with higher temps. Okay. But I also noticed the 3.0L Mercs have a V shape cuttout in the thermstat valve disc to enable some flow before getting on operating temp. and VP not (because of the supposed bypass, right...). But again, quite a difference between Merc and VP.

Additional Question #5 :

Can I put a temp sensor to the manifold instead of of a drain plug and connect a separate temp gauge connected to this just to keep an eye on this ? Is this technically okay ? (aside from a discussion on functional need).

Additional Question #6 :

Nothing to do with my issues but just want to understand this. Once upon a time a had a thermstat that was stuck open, why didn't the engine (here : the location of the sensor) eventually not get to normal operating temp, even after a decent load. I had that experience. Surprised me.Yes, in the first minutes I understand it flows out warm water. I would say the thermstat helps to get the engine block on temp QUICKLY and with a stuck open thermstat it takes longer. But it kept on 60 degr. celcius (again read sensor) !. Once thermstat was replaced it got to the normal operating temp. within minutes. Wonder what the mechanism was here.

Thanks for reading and if any suggestions I would welcome that. After 3 cracked manifolds I am rather nervous and wish to understand if the given solutions do not invoke new risks. The kids and wife really got fed up, that's bad since I wanted to introduce them to one of the greatest things there is, that freedom on the water : I know it, you know what it is, ... reliability is a thing, isn't it ? THANKS !

Regards,

Martijn,

Boating in The Netherlands

Glastron 175 SE, VP 3.0GSMBYMCE (that it was yeah)

Main issue #1 :

Cracked 3 exhaust manifolds, thinking bad casting work / valve lash heating up issues, etc and now found out, stupidly, that in thermostat housing 3850764 there is NO bypass hole to let cold / mixed water into the exhaust manifold as supposed to the design drawings. It isn't there, the actual casting is different from the design dwg's and an original VP supply on the engine, it simply can't even host this bypass. And yes, the manifold got hot but what did I know (as reference). Solved this now by putting a Merc housing on the engine with the VP therm. stat. Now my manifold keeps nicely on hand touching temp. Anyone known to this issue with that thermostat housing of VP ???, you know what a cracked manifold does to your engine ... Secondly, the temp. sensor doesn't pick this thing up on a 3.0L so that missing bypass is an engine killer potentially. Luckily I listen now better and check my gaskets always after starting and avoided serious water ingestion .... after learning it the hard way. Anyhow, too late when your gaskets leak.

Please, see also some pictures I added to get a visual on this.

Sub issue #2 :

Why does a 3.0GSMBYMCE flow raw water from the thermstat hsg to the riser directly ??? Is this to create a flow vacuum (for manifold suction) a/o acting as a pressure release function ? It seems not to be effective to stabilize the temperature house-holding at all and avoids picking up heat issues. Yeah, it avoids blowing your hoses by steam flashing. Merc. doesn't provide this (connection on the thermstat hsg to riser). So we plugged the riser hose. The riser, obviously gets now hotter and logically doesn't get warmer then the manifold now as it now only gets water from the manifold and keeps hand warm and thus slightly lower now then the manifold. It fits now to the overall thermal house-holding.The exhaust water temp out the drive is now higher, meaning it takes more heat out the system then it did. I was a bit afraid flow through the manifold would be too high to take heat out, actually it takes out better now. I guess it's about 60 degr. Celcius or a bit higher. In the former condition hardly water was entering the manifold, we investigated this (I guess no vacuum suction flow over the open thermstat from the bypass water flow and it was simply missing the volume from the bypass ...) The sensor temp. is at 75-80 degrees Celsius so the engine block itself keeps "as it was" on operating temp. as well, measured sensor temp according spec.

Thus with the Merc housing the manifold gets cold/mixed temp. water and feels okay, the riser is about the same temp. now. So the current design using the Merc approach seems to be okay. But perhaps someone of you can tell me if the riser needs that particular and basically direct raw water connection or any other risk with this?

Sub issue #3 :

The third time a cracked manifold, started searching barn finds this time (wife ain't enjoining my hobby anymore and eBay became to luxury for me

Observation #4 :

I noticed the Merc use lower temp. thermstats. although the re-circulation hose felt okay about 80-85 degrees Celsius the sensor gave a lower value to the gauge, still after (full ?) opening. So we installed the VP thermstat with higher temps. Okay. But I also noticed the 3.0L Mercs have a V shape cuttout in the thermstat valve disc to enable some flow before getting on operating temp. and VP not (because of the supposed bypass, right...). But again, quite a difference between Merc and VP.

Additional Question #5 :

Can I put a temp sensor to the manifold instead of of a drain plug and connect a separate temp gauge connected to this just to keep an eye on this ? Is this technically okay ? (aside from a discussion on functional need).

Additional Question #6 :

Nothing to do with my issues but just want to understand this. Once upon a time a had a thermstat that was stuck open, why didn't the engine (here : the location of the sensor) eventually not get to normal operating temp, even after a decent load. I had that experience. Surprised me.Yes, in the first minutes I understand it flows out warm water. I would say the thermstat helps to get the engine block on temp QUICKLY and with a stuck open thermstat it takes longer. But it kept on 60 degr. celcius (again read sensor) !. Once thermstat was replaced it got to the normal operating temp. within minutes. Wonder what the mechanism was here.

Thanks for reading and if any suggestions I would welcome that. After 3 cracked manifolds I am rather nervous and wish to understand if the given solutions do not invoke new risks. The kids and wife really got fed up, that's bad since I wanted to introduce them to one of the greatest things there is, that freedom on the water : I know it, you know what it is, ... reliability is a thing, isn't it ? THANKS !

Regards,

Martijn,

Boating in The Netherlands

Glastron 175 SE, VP 3.0GSMBYMCE (that it was yeah)