I replace a cracked block on a 1989 4.3 4bbl Quadra jet that had a mechanical fuel pump. When I bought the new rebuilt block it had the hole for the pump but it was cast solid inside, the mounting holes were not even drilled.so now I am stuck going to a electric pump.

I have done some Research on this and need to make sure I got it strait and ask a few questions.

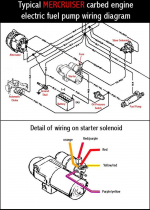

1. For electric I tap off of the purple wire and run to one side of the oil pressure switch, then another wire from the switch to the pump. Then ground the pump. Electrically is that is all there is too it? I am using the pen mercruiser electric pump.

2. For fuel delivery, I can not find a good picture of where the pump is mounted from the factory, can somebody please tell me where they usually or post a picture.

3. How far from the tank or from the engine can the factory electric pump be mounted?

4. Is there a vent return or fuel return from the carburetor back to the pump or tank? Seems like if there wasn’t a return it would push too much fuel and flood the carburetor.

I have done some Research on this and need to make sure I got it strait and ask a few questions.

1. For electric I tap off of the purple wire and run to one side of the oil pressure switch, then another wire from the switch to the pump. Then ground the pump. Electrically is that is all there is too it? I am using the pen mercruiser electric pump.

2. For fuel delivery, I can not find a good picture of where the pump is mounted from the factory, can somebody please tell me where they usually or post a picture.

3. How far from the tank or from the engine can the factory electric pump be mounted?

4. Is there a vent return or fuel return from the carburetor back to the pump or tank? Seems like if there wasn’t a return it would push too much fuel and flood the carburetor.