lexkyboater

Petty Officer 2nd Class

- Joined

- Apr 9, 2007

- Messages

- 191

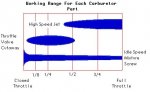

This old motor starts and runs good at low rpm. I've already replaced water pump, lower prop shaft seal and fuel pump. At WOT, squeezing the bulb doesn't help to make it run better (although it did before the new fuel pump!). I've rebuilt carb (didn't replace expansion plugs) and made sure I blew out the high speed jet and the port, and even made sure the jet was .048 with a drill bit. It was initially quite gunky. I also replaced points, plugs and condensors, but not the coils and plug wires. Plug wires seem in decent shape. Coils checked out with primary and secondary resistance at 1.0 ohms and 7 thousand ohms, respectively. Adjusted points according to the excellent article at http://outboard-boat-motor-repair.c... 5.5 HP 1954-1964 Ignition System Tune-up.htm, under the section "A simple but effective method to test the ignition timing." If you haven't seen this before, you should take a look. I've always blindly gapped my points at 0.020 or whatever at the top of the cam lobe but this guy correctly pointed out that's just a starting point. When the points open, the plugs fire, and you need to set them to open with the timing mark on the flywheel.

Noticed that there are broken sections of insulation on the wires going from the points to the stop button/kill switch. Bought some electrical sealer/liquid tape and am going to try sealing those wires just in case. The coils look like they've been replaced as they have a nice rubber coating around them, but the wires going from the coils have old looking insulation on them, so may try the electrical sealer on them too. Haven't run at night yet to see any arcing. Link and Sync done when carb was rebuilt and the butterfly on the carb opens all the way up as the timing advances. Looks right. Am also in the process of decarbing, and have sprayed it 3 times now and letting it sit for the day with Deep Creep.

Took out yesterday morning and it ran good and clean for about 5 seconds, then started missing/bogging and slowing down and stops planing well. Seems electrical to me. I took the flywheel off again and found that I hadn't tightened the screw on the front coil's condensor. When I tighted it back down, still missing and won't rev out. Since that condensor wasn't tightened down, did that ruin it? I bought two new condensors just to make sure but haven't replaced yet. I also haven't checked that the plugs are firing consistently after taking them out and holding them to engine ground. Maybe I have a few things left to do, but I've had this thing out 5 times now and will hopefully get it solved. Any other tips?

Noticed that there are broken sections of insulation on the wires going from the points to the stop button/kill switch. Bought some electrical sealer/liquid tape and am going to try sealing those wires just in case. The coils look like they've been replaced as they have a nice rubber coating around them, but the wires going from the coils have old looking insulation on them, so may try the electrical sealer on them too. Haven't run at night yet to see any arcing. Link and Sync done when carb was rebuilt and the butterfly on the carb opens all the way up as the timing advances. Looks right. Am also in the process of decarbing, and have sprayed it 3 times now and letting it sit for the day with Deep Creep.

Took out yesterday morning and it ran good and clean for about 5 seconds, then started missing/bogging and slowing down and stops planing well. Seems electrical to me. I took the flywheel off again and found that I hadn't tightened the screw on the front coil's condensor. When I tighted it back down, still missing and won't rev out. Since that condensor wasn't tightened down, did that ruin it? I bought two new condensors just to make sure but haven't replaced yet. I also haven't checked that the plugs are firing consistently after taking them out and holding them to engine ground. Maybe I have a few things left to do, but I've had this thing out 5 times now and will hopefully get it solved. Any other tips?