LiLGrady17

Seaman

- Joined

- May 1, 2008

- Messages

- 67

I was having trouble keeping the engine running once started, but wasnt sure if it was a carb or some other problem. To isolate it, I swapped on a set of carbs from a '76 evinrude 85 from a parts motor to see if the condition changed at all. The engine now ran, but #1 cyl was running rich & missing, sometimes coughing out when I brought the idle down.. I re-did the compression test the correct way, and got pressures of

#2-110 #1-90

#4-110 #3-95

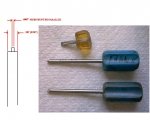

Now, heres the kicker. I was going through the Seloc to see if there are any idle mixture adjustments to be made, and it says there is an idle speed needle valve to adjust but I cant find it on the carb. So I took out the plug over the Low Speed orifice, started the engine thinking I could adjust the orifice and the engine's idle was better. Being amazed by this, I started trying different things. I found out if I keep the LS orifice uncovered, drape a clean rag over the carb inlets, #1 cylinder picks up, Idle smooths out and idles nicely at 7-800 in neutral. Is there an idle speed adjustment to be made on these carbs, and what should I be looking for when I rebuild the carbs to correct this? Thanks

#2-110 #1-90

#4-110 #3-95

Now, heres the kicker. I was going through the Seloc to see if there are any idle mixture adjustments to be made, and it says there is an idle speed needle valve to adjust but I cant find it on the carb. So I took out the plug over the Low Speed orifice, started the engine thinking I could adjust the orifice and the engine's idle was better. Being amazed by this, I started trying different things. I found out if I keep the LS orifice uncovered, drape a clean rag over the carb inlets, #1 cylinder picks up, Idle smooths out and idles nicely at 7-800 in neutral. Is there an idle speed adjustment to be made on these carbs, and what should I be looking for when I rebuild the carbs to correct this? Thanks