Weirdboymike

Seaman

- Joined

- Apr 9, 2015

- Messages

- 59

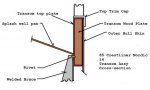

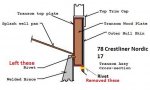

Hi there, I have been a long time follower and fans of the posts here and found a lot of them very helpful. I am however just starting to plunge into a BIG project I have been putting off for quite some time now. About 5 years back I purchased my boat from a friend who just needed it gone. Got the 17' Nordic (1978 vintage), with trailer, and motor (1977 70hp Evinrude) for $450 bucks!! The motor has been running like a champ after some initial tuning. Anywho the flooring has been rotting for quite some time now as they stored it out side (no cover). I knew this going in that I would need to redo the whole thing but thought it would be good to customize it a bit anyway. I LOVE Deep V's. I just tore out the floor and consoles and looking for advice along the way. I was surprised to see that the foam wasn't saturated and pretty relieved too as I am trying to do this on a budget (student loans are beating me up). I am now looking at replacing the transom before I get the new floor in. I haven't tore into it too much yet as weather has been a little wet and I need to do this out doors as my garage isn't big enough for this beast (the pics with it in the garage are from when I rented a house with a large garage). Anyway just looking for advise and any tips that anyone might have for me. My first and most urgent question is... How difficult is it going to be to remove the transom? Any tips? If I remove the transom cap will the wood be exposed? Will I need to remove the splash well and if so, how difficult would that be (is it just riveted/screwed, or welded under the transom cap? Anyone restore one of these before? I was following eyes4u can I attempt to message him directly here? He has almost the exact same boat and would like to pick his brain a little.