Hi All,

I have a 98 SeaRay where both sides of the floor near the stern are soft. I did a few small core samples, and the inside is all mush. I estimate about 1.5' x 3' is soft on each side right near the center (not the stringers). Water most likely got in on one side when previous owner kept re-drilling holes that had stripped and never filled them. I don't know how it got in on the other side, which worries me. I see people here always find the rot worse than expected. I'm hoping this is as it appears since its relatively new and I'm quite pissed that a 98 boat is already rotting.

Talked to a local fiberglass guy today and he said only take the top layer of fiberglass off, scrap out the rotted wood and then re-fiberglass. Seems like most people here advise to rip up both layers to check for additional rot. Problem is there is no good way to join the new fiberglass with the existing, since I most likely will not be going to stringers (at least on front/back sides). Any advice how to join this?

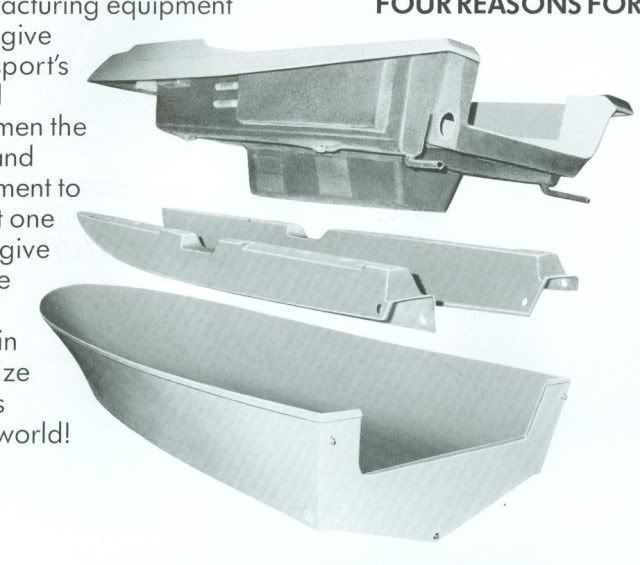

As you can see the rest of the boat is in good condition. I'm very concerned with getting the gelcoat to look professional. The non-slip goes to about the last inch which starts wrapping up the side which is glossy. Not sure how to get that non-slip to gloss edge perfect. I'm debating of doing the fiberglass myself, and then bring in for professional gelcoat spray. If I attempt myself, I will only roll.

I may also try to do something creative with the backing since all rain water in the boat drains backwards past a piece of plywood wrapped in carpet. Of course that is rotting because its the stupidest design SeaRay could have ever come up with! Further a few inches of water can collect in the back corners, especially sitting idle on a trailer. I dont know what they were thinking. Any ideas welcome.

Boat is all vinylester which I will use. I'm planning 2 layers of CSM on each side of plywood, and to have 1808 on hand in case its needed. I will fiberglass this fall, and gelcoat next spring.

I have a 98 SeaRay where both sides of the floor near the stern are soft. I did a few small core samples, and the inside is all mush. I estimate about 1.5' x 3' is soft on each side right near the center (not the stringers). Water most likely got in on one side when previous owner kept re-drilling holes that had stripped and never filled them. I don't know how it got in on the other side, which worries me. I see people here always find the rot worse than expected. I'm hoping this is as it appears since its relatively new and I'm quite pissed that a 98 boat is already rotting.

Talked to a local fiberglass guy today and he said only take the top layer of fiberglass off, scrap out the rotted wood and then re-fiberglass. Seems like most people here advise to rip up both layers to check for additional rot. Problem is there is no good way to join the new fiberglass with the existing, since I most likely will not be going to stringers (at least on front/back sides). Any advice how to join this?

As you can see the rest of the boat is in good condition. I'm very concerned with getting the gelcoat to look professional. The non-slip goes to about the last inch which starts wrapping up the side which is glossy. Not sure how to get that non-slip to gloss edge perfect. I'm debating of doing the fiberglass myself, and then bring in for professional gelcoat spray. If I attempt myself, I will only roll.

I may also try to do something creative with the backing since all rain water in the boat drains backwards past a piece of plywood wrapped in carpet. Of course that is rotting because its the stupidest design SeaRay could have ever come up with! Further a few inches of water can collect in the back corners, especially sitting idle on a trailer. I dont know what they were thinking. Any ideas welcome.

Boat is all vinylester which I will use. I'm planning 2 layers of CSM on each side of plywood, and to have 1808 on hand in case its needed. I will fiberglass this fall, and gelcoat next spring.

Last edited: