Hello all,

I am working on replacing all of the bellows, shift cable etc on a boat with an alpha one gen two. 94' vintage I believe. This particular model has the oil reservoir for the drive which is great, however the oil hose between the transom housing and the bellhousing was pretty cracked and dry rotted so I decided to replace that as well while I had everything apart.

Unfortunately the hose barb on the outside of the boat slightly broke when I was trying to put a new hose on. This model has the BRASS version, NOT the plastic one. It's probably still usable since its hard to telll if it broke or just bent slightly but I'd like to replace it. I have removed the right angle fitting, nut and washer inside of the boat but can't seem to get that sucker out. I have tapped on it with a stiff rubber mallet, even put the nut back on and used a metal hammer (lightly). It hasn't budged quite yet. Any tips on getting this thing out? I tried applying a little heat on the outside too but its hard since the plastic water tube is right above it.

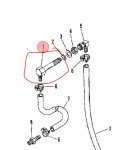

The part I'm talking about is circled in red on the attached picture. Any ideas are greatly appreciated!

I am working on replacing all of the bellows, shift cable etc on a boat with an alpha one gen two. 94' vintage I believe. This particular model has the oil reservoir for the drive which is great, however the oil hose between the transom housing and the bellhousing was pretty cracked and dry rotted so I decided to replace that as well while I had everything apart.

Unfortunately the hose barb on the outside of the boat slightly broke when I was trying to put a new hose on. This model has the BRASS version, NOT the plastic one. It's probably still usable since its hard to telll if it broke or just bent slightly but I'd like to replace it. I have removed the right angle fitting, nut and washer inside of the boat but can't seem to get that sucker out. I have tapped on it with a stiff rubber mallet, even put the nut back on and used a metal hammer (lightly). It hasn't budged quite yet. Any tips on getting this thing out? I tried applying a little heat on the outside too but its hard since the plastic water tube is right above it.

The part I'm talking about is circled in red on the attached picture. Any ideas are greatly appreciated!