toneeees

Administrator

- Joined

- Mar 15, 2011

- Messages

- 3,024

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Working on a marine electrical system is a near certainty if you're a hands-on boat owner. It doesn't matter if your foray into the jungle of your boat's wiring is voluntary - adding electronics or accessories, or involuntary - troubleshooting and repairing an electrical malfunction, there is a right way to get the job done.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Each of the following five tips outline the proper methods and materials for common boat wiring scenarios. These aren't simply our own ideas - they're a compilation of legitimate Federal Regulations for boat builders from the U.S. Coast Guard (USCG) and best practices established by the American Boat & Yacht Council (ABYC). Remember, direct current (DC) electrical systems use two wires - positive (+) and negative (-).[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip #1: Use Only Marine Wire

Your boat is a dynamic, moving structure that lives its life in a bumpy, damp environment; the wiring must be flexible and corrosion-resistant.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Single strand household wire won't work - the boat's inherent movements, vibrations and dramatic temperature changes will break solid single strand wire. Automotive wire looks a lot like marine wire (as does a lamp cord), but lacks moisture resistance and will eventually lead to corrosion-related failures.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

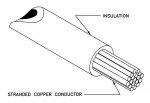

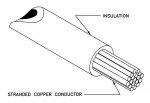

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Generically, marine wire is a multi-strand copper conductor that is electroplated with tin (tinned) for corrosion resistance, sheathed within its water and high-temperature resistant insulated covering. Type 3 marine wire, containing the maximum number of individual strands per cross-sectional area, with an insulation rating of BC5W2 (105?C/221?F dry, 75?C/167?F wet) is the best choice for most of the common wiring tasks on a pleasure boat.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip #2: Use the Proper Size Wire

Marine wire uses the American Wire Gauge (AWG) system for designating the various wire diameters (gauges). Small gauge numbers indicate a large wire diameter; conversely, small diameter wires carry a large gauge designation.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]For example, 0 AWG is about 0.420" diameter (not including the insulation), while 16 AWG is roughly 0.060" in diameter (excluding insulation).[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]The larger the wire (small AWG size), the more current it will carry, with a minimum amount of resistance.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

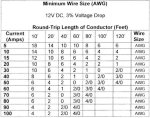

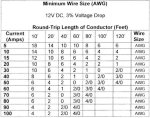

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]To determine what gauge wire to use, you must factor in how much electricity (volts), the load of the device (amperage), voltage drop (electricity lost due to the loads and wiring resistance), and the actual length of the wiring run - from the power source to the device and back. This isn't a straight-line measurement, but the distance through bulkheads and around obstacles; the real world amount of wire necessary to do the job.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip # 3: Avoid Splices

Using the true measurements from the electrical device to the power source, add a few feet to give yourself a little extra wire, just in case your calculations are off a bit. It's easier to trim excess wire than it is to splice in an additional couple of feet.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Splices compromise the integrity of the wiring, and are often the sources of hair-pulling troubleshooting exercises as these connections invariably work loose or corrode at the most inconvenient times.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip # 4: Make Good Connections

Marine-grade crimp connectors sealed with adhesive heat-shrink tubing ensure that connections are solid and repel moisture intrusion. Don't skimp and use the cheap stuff from auto parts stores or big-box home improvement centers. Home and auto electrical hardware doesn't hold up in a rough and wet boating installation.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Marine connectors should be tin-coated copper; no unplated steel or aluminum, no electrical tape or wire nuts are acceptable on a boat. Crimp connectors with a dedicated crimping tool. Ratchet-style crimpers clamp down the connectors precisely every time with a minimum of effort; we recommend these if you're doing a lot of rewiring on your boat.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Plain hand-held crimping tools are fine for the occasional repair and aren't as pricey as ratchet crimpers, but you'll need to practice to acquire a feel for how hard to squeeze the crimpers to prevent crushing the various sizes of connectors.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip #5: Keep It High and Dry

Route wiring high in the boat, in a location as protected from the elements as possible to prevent water intrusion into the electrical system.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Also, support the wiring by routing the wires through a rigging tube or heat-resistant conduit (with drainage holes every several inches). Another option is to use plastic hangers or tie-straps (eyelet style) placed approximately 18" apart to secure wiring bundles.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

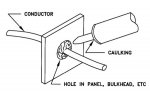

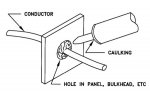

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]If you must run wires through a bulkhead, use a grommet bushing or sealant/caulking to prevent the wiring from chafing against the sides of the hole in the bulkhead.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]To find a wide selection of marine grade wiring, connectors, controls, switches and other electrical installation accessories just click here: http://www.iboats.com/Marine-Electrical-Lights-Wiring-Batteries-Switches/dm/view_id.5[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] Photos and illustrations provided by author, Yamaha Marine, Nimmer Marine and iboats.com.

Photos and illustrations provided by author, Yamaha Marine, Nimmer Marine and iboats.com.

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Each of the following five tips outline the proper methods and materials for common boat wiring scenarios. These aren't simply our own ideas - they're a compilation of legitimate Federal Regulations for boat builders from the U.S. Coast Guard (USCG) and best practices established by the American Boat & Yacht Council (ABYC). Remember, direct current (DC) electrical systems use two wires - positive (+) and negative (-).[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip #1: Use Only Marine Wire

Your boat is a dynamic, moving structure that lives its life in a bumpy, damp environment; the wiring must be flexible and corrosion-resistant.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Single strand household wire won't work - the boat's inherent movements, vibrations and dramatic temperature changes will break solid single strand wire. Automotive wire looks a lot like marine wire (as does a lamp cord), but lacks moisture resistance and will eventually lead to corrosion-related failures.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Generically, marine wire is a multi-strand copper conductor that is electroplated with tin (tinned) for corrosion resistance, sheathed within its water and high-temperature resistant insulated covering. Type 3 marine wire, containing the maximum number of individual strands per cross-sectional area, with an insulation rating of BC5W2 (105?C/221?F dry, 75?C/167?F wet) is the best choice for most of the common wiring tasks on a pleasure boat.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip #2: Use the Proper Size Wire

Marine wire uses the American Wire Gauge (AWG) system for designating the various wire diameters (gauges). Small gauge numbers indicate a large wire diameter; conversely, small diameter wires carry a large gauge designation.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]For example, 0 AWG is about 0.420" diameter (not including the insulation), while 16 AWG is roughly 0.060" in diameter (excluding insulation).[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]The larger the wire (small AWG size), the more current it will carry, with a minimum amount of resistance.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]To determine what gauge wire to use, you must factor in how much electricity (volts), the load of the device (amperage), voltage drop (electricity lost due to the loads and wiring resistance), and the actual length of the wiring run - from the power source to the device and back. This isn't a straight-line measurement, but the distance through bulkheads and around obstacles; the real world amount of wire necessary to do the job.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip # 3: Avoid Splices

Using the true measurements from the electrical device to the power source, add a few feet to give yourself a little extra wire, just in case your calculations are off a bit. It's easier to trim excess wire than it is to splice in an additional couple of feet.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Splices compromise the integrity of the wiring, and are often the sources of hair-pulling troubleshooting exercises as these connections invariably work loose or corrode at the most inconvenient times.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip # 4: Make Good Connections

Marine-grade crimp connectors sealed with adhesive heat-shrink tubing ensure that connections are solid and repel moisture intrusion. Don't skimp and use the cheap stuff from auto parts stores or big-box home improvement centers. Home and auto electrical hardware doesn't hold up in a rough and wet boating installation.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Marine connectors should be tin-coated copper; no unplated steel or aluminum, no electrical tape or wire nuts are acceptable on a boat. Crimp connectors with a dedicated crimping tool. Ratchet-style crimpers clamp down the connectors precisely every time with a minimum of effort; we recommend these if you're doing a lot of rewiring on your boat.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Plain hand-held crimping tools are fine for the occasional repair and aren't as pricey as ratchet crimpers, but you'll need to practice to acquire a feel for how hard to squeeze the crimpers to prevent crushing the various sizes of connectors.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Tip #5: Keep It High and Dry

Route wiring high in the boat, in a location as protected from the elements as possible to prevent water intrusion into the electrical system.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Also, support the wiring by routing the wires through a rigging tube or heat-resistant conduit (with drainage holes every several inches). Another option is to use plastic hangers or tie-straps (eyelet style) placed approximately 18" apart to secure wiring bundles.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]If you must run wires through a bulkhead, use a grommet bushing or sealant/caulking to prevent the wiring from chafing against the sides of the hole in the bulkhead.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]To find a wide selection of marine grade wiring, connectors, controls, switches and other electrical installation accessories just click here: http://www.iboats.com/Marine-Electrical-Lights-Wiring-Batteries-Switches/dm/view_id.5[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]