Re: Bad compression on Johnson 6 hp 1973

It is not unusual for a rope start engine to compress in that range, Martin. I think if you do a decarbon procedure and test again (exactly as described in the Top Secret file) your concern will be relieved.

In 60+ years of messing with outboards I have never seen one wear out, but I have seen many destroyed by neglect, abuse and misdiagnosis. Your engine is not even 40 years old!

I think your problem has to do with the linkage involved in throttle position and ignition timing. A careful "link 'n' synch" procedure, by the book, is in order. Failing that, investigate carburetor clogging.

Good luck.

I agree with JB. The only thing that I could suggest in addition to JB suggestions is to check that you have good spark on both cylinders. You maybe dropping a cylinder and running on one. Running on one cylinder the motor will idle ok, but will have diminished power.

Went fishing with father-n-law one time and I told that his 6hp Evinrude was running kind weak, but he states it was getting old and worn. It idle ok. So, he had been fishing for months in that present state. He said it got him to the fishing hole and back reliably, but just a little slower.

So, I checked his ignition and the top bottom cylinder was out. So I check under the flywheel and he had a cracked coil, so I changed both coils. The points and condenser were fine and I replaced the oil wicker.

She cranked up beautifully and that little motor now planes his little boat and zooms all over and run like she should. 1968 6hp Evinrude....great little motors.

Another suggestion is to make sure the motor is getting cooled and the water pump is working. If it over heated at one point, it could have compromised your cylinder head gasket or slightly warped your cylinder head. Easy fix.

If every thing else check out and decarbing does not help your compression. Remove your cylinder head. Clean the mating surfaces and apply a new head gasket and re-torque the screws to

60 to 80 inch pounds. Notice I stated inch pounds.

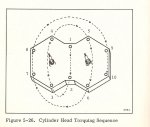

Make sure the cylinder head is flat. Here is a diagram that explains it. Wet the surface lightly and use a figure 8 pattern until the all the surface is shiny. click on the thumb pic.

The torque pattern is an attachment to this post. First past of the torque pattern is 50% torque value, the second pass is 100% torque value, and after you run the motor and it is good and warm up, stop it let cool some and re-torque again for the final time at 100% torque value.

Hope this helps. Take care.