Hi wondered if anyone could help please.

Trying to install the engine and I believe am missing something.

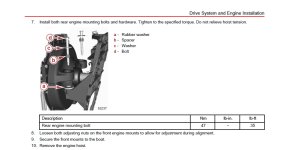

Everything was lined up and the rear mounting bolts all installed and located into the bottom nut.

The spacer is proud of the flywheel mounting fixing by some margin and there is a large gap under the washer – it just doesn’t look right.

I wondered if the spacer is “pressed” into the flywheel mounting fixing?

I have not tightened it up it up in case this was wrong!!

On top of that the alignment is way off (too low). Which I don’t understand, even by adjusting the mounting feet, unless the spacer is designed to lift the engine because the "gap" is about the same?

Unfortunately I had to let the yard crane go until another time when I am surer of the procedures.

Appreciate any pointers.

Thank you.

Trying to install the engine and I believe am missing something.

Everything was lined up and the rear mounting bolts all installed and located into the bottom nut.

The spacer is proud of the flywheel mounting fixing by some margin and there is a large gap under the washer – it just doesn’t look right.

I wondered if the spacer is “pressed” into the flywheel mounting fixing?

I have not tightened it up it up in case this was wrong!!

On top of that the alignment is way off (too low). Which I don’t understand, even by adjusting the mounting feet, unless the spacer is designed to lift the engine because the "gap" is about the same?

Unfortunately I had to let the yard crane go until another time when I am surer of the procedures.

Appreciate any pointers.

Thank you.