I have a 1998 115 2+2 with 800 hours on it. This winter I replaced the water pump impeller and decided to replace the seals under the water pump housing.

When I removed the seals I noticed that they had worn grooves in the sealing surface, which would reduce the life and effectiveness of new seals.

By design, the sealing surface is replaceable, but it requires removal of the driveshaft, which in turn requires that the entire lower unit be disassembled.

I did some research and decided that some Speedi Sleeves could be used to repair the shaft. Speedi Sleeves are stainless steel wear rings commonly used in industry to repair seal surfaces on shafts. They are ground to exact dimensions so that they press on to the shaft. A speedi Sleeve is only 0.003? thick, so the original seal can be used.

The correct Speedi Sleeve part number for this application is CR 99103

Here is a picture showing the grooves in the drive shaft. These grooves aren?t real bad, and just replacing the seals probably would have worked OK, but I wanted to try the Speedi Sleeve solution.

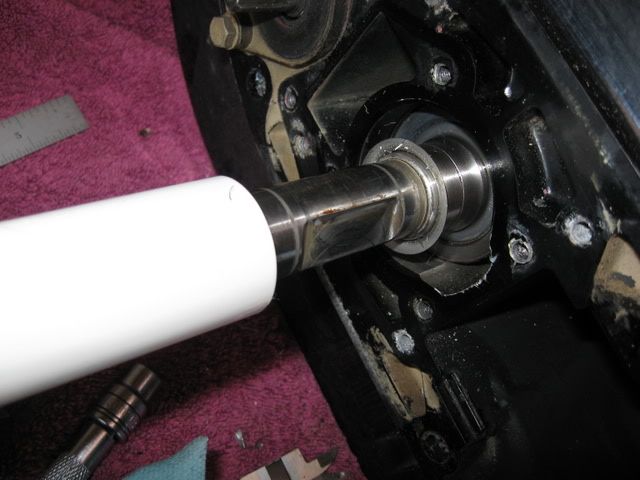

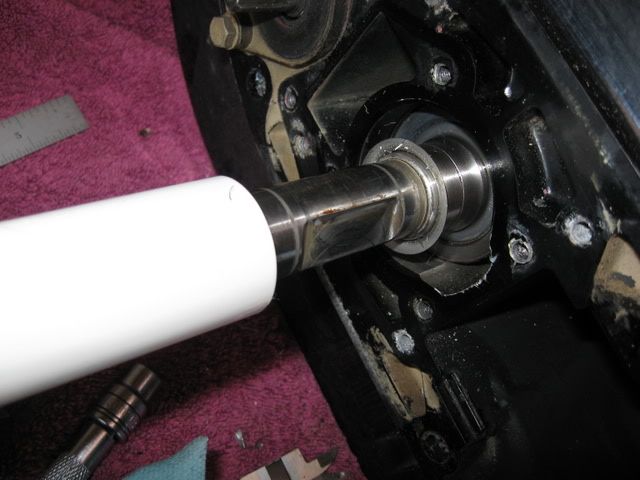

I had to use 2 sleeves, as there are 2 seals that are spaced too far apart for a single sleeve. This picture shows the first sleeve pressed in place. I used a piece of PVC pipe and a rubber mallet to pound the sleeve in place.

I have actually pressed the sleeve on ?backwards?, but the radius on the wear surface of the shaft allowed me to get the sleeve started, and if I had pressed it on the other way I would not have been able to get the flange off of the sleeve.

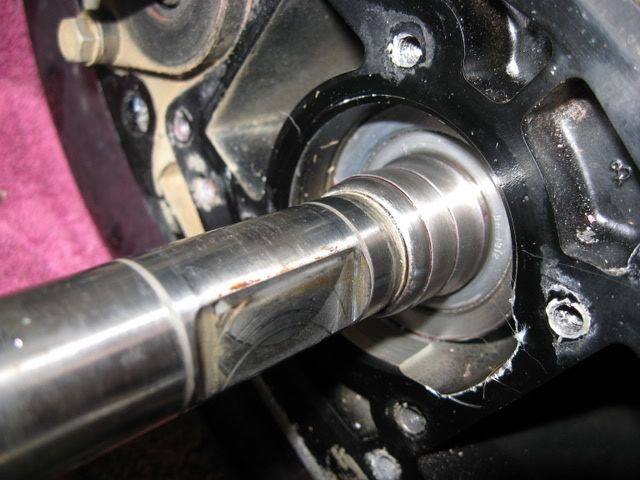

This picture shows the second sleeve pressed on to the shaft. Note the PVC pipe is visible on the left. You can also see that I?ve removed the flange from the 1st sleeve before pressing the 2nd sleeve on.

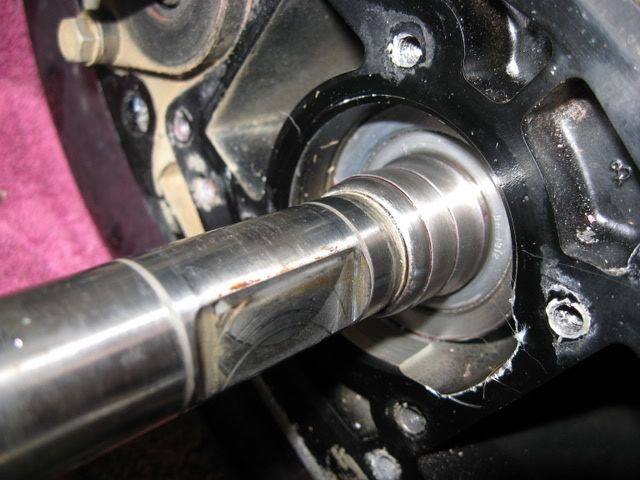

And finally, here is a picture of both sleeves in place.

I?m expecting that this repair will last for the rest of the life of the engine.

When I removed the seals I noticed that they had worn grooves in the sealing surface, which would reduce the life and effectiveness of new seals.

By design, the sealing surface is replaceable, but it requires removal of the driveshaft, which in turn requires that the entire lower unit be disassembled.

I did some research and decided that some Speedi Sleeves could be used to repair the shaft. Speedi Sleeves are stainless steel wear rings commonly used in industry to repair seal surfaces on shafts. They are ground to exact dimensions so that they press on to the shaft. A speedi Sleeve is only 0.003? thick, so the original seal can be used.

The correct Speedi Sleeve part number for this application is CR 99103

Here is a picture showing the grooves in the drive shaft. These grooves aren?t real bad, and just replacing the seals probably would have worked OK, but I wanted to try the Speedi Sleeve solution.

I had to use 2 sleeves, as there are 2 seals that are spaced too far apart for a single sleeve. This picture shows the first sleeve pressed in place. I used a piece of PVC pipe and a rubber mallet to pound the sleeve in place.

I have actually pressed the sleeve on ?backwards?, but the radius on the wear surface of the shaft allowed me to get the sleeve started, and if I had pressed it on the other way I would not have been able to get the flange off of the sleeve.

This picture shows the second sleeve pressed on to the shaft. Note the PVC pipe is visible on the left. You can also see that I?ve removed the flange from the 1st sleeve before pressing the 2nd sleeve on.

And finally, here is a picture of both sleeves in place.

I?m expecting that this repair will last for the rest of the life of the engine.