Hi,

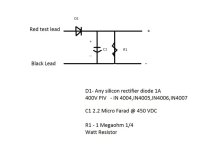

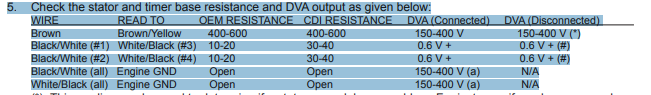

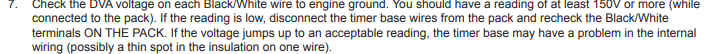

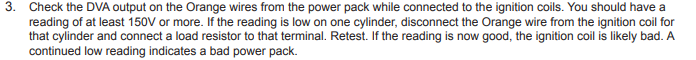

I have a few 1970's V4 crossflows. Part of the ignition troubleshooting is to measure the output from sensor wires to gnd and orange coil wires to gnd. These are supposed to be 150V. I have never got this to work using my homemade DVA adapter. It seems to work fine for stator measurement and the sensor signal across sensor wires 1 to 3 and 2 to 4.

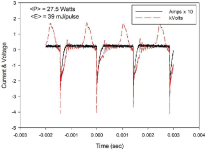

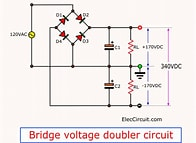

Last week I bit the bullet and bought a ESI DVA adapter. I was disappointed to find that it seems no better than my homemade one for these measurements. It basically gets to like 1 or 2 volts reading (and takes a while to even get this high) where it should be 150V plus. I am thinking that this may be due to the intermittent nature of these signals in a 4 cylinder motor. Presumably this would be even more challenging on a 6 cylinder.

Has anyone else had difficulty with these measurements?

Does anyone know if the ESI analog meter with DVA function capture these signals better?

I have read that they work better for the low voltage signal across the sensor wires due to not having the voltage drop associated with the diode in a DVA adapter which can give misleadingly low reading but I have no issue with this.

I don't want to fork out for another device if it will also have the same issue.

I have a few 1970's V4 crossflows. Part of the ignition troubleshooting is to measure the output from sensor wires to gnd and orange coil wires to gnd. These are supposed to be 150V. I have never got this to work using my homemade DVA adapter. It seems to work fine for stator measurement and the sensor signal across sensor wires 1 to 3 and 2 to 4.

Last week I bit the bullet and bought a ESI DVA adapter. I was disappointed to find that it seems no better than my homemade one for these measurements. It basically gets to like 1 or 2 volts reading (and takes a while to even get this high) where it should be 150V plus. I am thinking that this may be due to the intermittent nature of these signals in a 4 cylinder motor. Presumably this would be even more challenging on a 6 cylinder.

Has anyone else had difficulty with these measurements?

Does anyone know if the ESI analog meter with DVA function capture these signals better?

I have read that they work better for the low voltage signal across the sensor wires due to not having the voltage drop associated with the diode in a DVA adapter which can give misleadingly low reading but I have no issue with this.

I don't want to fork out for another device if it will also have the same issue.