76SeaRay

Lieutenant Junior Grade

- Joined

- Aug 24, 2017

- Messages

- 1,071

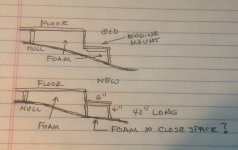

The factory originally left all the stringers pretty much floating on the inside. They relied upon the foam to just flow under all the stringers and fill all the spaces. That allowed the floor to bow up under the pressure from the foam. I am bedding all of the new ones.

In the motor mount area I have brought the stringer down to the hull for better strength for the floor and motor mounts but that creates an enclosed space under the motor mounts. What is the best way to fill the space with foam, that is, best way to drill holes as fill ports? I don't like the idea of drilling from the top or the inside step. Thinking about just drilling a hole from the outboard side of the stringer and in the front and back to fill from each. I would drill a vent hole in the middle to make sure it fills.

Two other questions, what is the best foam to use and how much would be needed to fill the cavity 4 inches by 6 inches by 42 inches long?

Thanks...

In the motor mount area I have brought the stringer down to the hull for better strength for the floor and motor mounts but that creates an enclosed space under the motor mounts. What is the best way to fill the space with foam, that is, best way to drill holes as fill ports? I don't like the idea of drilling from the top or the inside step. Thinking about just drilling a hole from the outboard side of the stringer and in the front and back to fill from each. I would drill a vent hole in the middle to make sure it fills.

Two other questions, what is the best foam to use and how much would be needed to fill the cavity 4 inches by 6 inches by 42 inches long?

Thanks...