altitude 411

Petty Officer 3rd Class

- Joined

- May 24, 2018

- Messages

- 78

Just rebuilt my 1988 force 125 with Wiesco pistons .030 over sized. All gaskets and seals were replaced. I was following break in procedure and was about 7-8 hrs in when I noticed the exhaust plate gasket was weeping water. The engine seemed to be running OK and would idle and start fine. I had just started to open up to 3/4 throttle and change rpms frequently.

I have torn the engine down to the point that I have removed exhaust head and exhaust plate.

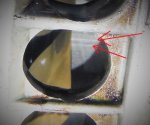

Question: 1) Is it common to have a warped exhaust plate or should it be flat? Mine was warped when I rebuilt the engine and at the time I thought that since it was exposed to heat from the exhaust and also water that it might be common to be warped. Is this the cause of the gaskets not sealing ? Should I have used a sealant on the gaskets?

Here is a video of the leak just before I tore the engine down to investigate. https://www.youtube.com/watch?v=X_AbOv8Gk5o

Do you think I did the engine harm? there is oil on the water side of the exhaust so I believe water was also getting in the combustion chambers. Would you recommend replacing the rings and starting the break-in procedure over? Should I spray WD-40 in the cylinders while I'm waiting for new gaskets and exhaust plate to help displace any water to prevent rusting? I will have this repaired by the weekend.

included some photos of piston/cylinder/rings after leak as well as exhaust plate.

Thanks for any comments and/or advise in this matter

I have torn the engine down to the point that I have removed exhaust head and exhaust plate.

Question: 1) Is it common to have a warped exhaust plate or should it be flat? Mine was warped when I rebuilt the engine and at the time I thought that since it was exposed to heat from the exhaust and also water that it might be common to be warped. Is this the cause of the gaskets not sealing ? Should I have used a sealant on the gaskets?

Here is a video of the leak just before I tore the engine down to investigate. https://www.youtube.com/watch?v=X_AbOv8Gk5o

Do you think I did the engine harm? there is oil on the water side of the exhaust so I believe water was also getting in the combustion chambers. Would you recommend replacing the rings and starting the break-in procedure over? Should I spray WD-40 in the cylinders while I'm waiting for new gaskets and exhaust plate to help displace any water to prevent rusting? I will have this repaired by the weekend.

included some photos of piston/cylinder/rings after leak as well as exhaust plate.

Thanks for any comments and/or advise in this matter

Attachments

Last edited: