Grtflashflyer

Recruit

- Joined

- Oct 12, 2012

- Messages

- 4

Hi all.

I am new to iboats forum and I would like to post a question, greatly appreciate any feed back.

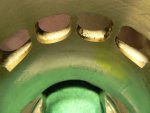

Brief: Recently had my 1978 85hp Chrysler Charger pulled down for a rebuild, it was due for its final at 3.352 .040 oversize but received a call from machinist that the middle cylinder was out of round and already at this size, so in an attempt to get more out of the block it was pushed out to 3.375. Ordered pistons had rings fitted then found out the pistons were top loading 19.5mm piston pin variety (Force 1996 and up). Not suited to my connecting rods at all.

The connecting rod for this piston is 6mm longer and requires 29 wrist pin bearings not 26.

Q; If I purchase Force con-rod # 640N O.E. #640-9612A7 with pin needles #010-136-29, lower rod caged bearings #010-150, will this application fit my crank. So, there lays the question, is the crank circumference the same on a 1978 85hp Chrysler as it is on a Force 75 - 90 hp of the year 1996 and up.

Many thanks.

I am new to iboats forum and I would like to post a question, greatly appreciate any feed back.

Brief: Recently had my 1978 85hp Chrysler Charger pulled down for a rebuild, it was due for its final at 3.352 .040 oversize but received a call from machinist that the middle cylinder was out of round and already at this size, so in an attempt to get more out of the block it was pushed out to 3.375. Ordered pistons had rings fitted then found out the pistons were top loading 19.5mm piston pin variety (Force 1996 and up). Not suited to my connecting rods at all.

The connecting rod for this piston is 6mm longer and requires 29 wrist pin bearings not 26.

Q; If I purchase Force con-rod # 640N O.E. #640-9612A7 with pin needles #010-136-29, lower rod caged bearings #010-150, will this application fit my crank. So, there lays the question, is the crank circumference the same on a 1978 85hp Chrysler as it is on a Force 75 - 90 hp of the year 1996 and up.

Many thanks.