Fuel pump on my 4.3 gxi started to whine already a while ago. Checked the fuel pressure regulator, there black dots visible so diagnosis on the paint problem was put. Ordered myself new pumps and opened up the fuel cell.

The filter side was really good condition

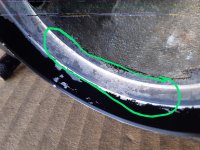

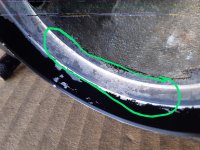

Ok, so I thought must be somewhere else and opened up the cooler side. Indeed, there was a small paint chip missing near the backflow tube.

Naturally I assumed that this is only the beginning and it is on the verge of totally peeling away. But was I wrong, after two days and probably like 15 times with 3 different paint removers this is where I am...

The damn paint just wont come off. So the question is it now too late to turn back and assemble everything as it is, or will it now definitely start to peel away bit by bit?

At the same time, the waterjacket side seems to have pitting just in the places where the O-rings would sit. Will it it hold or will I have leaks?

Any recommendations on how to move on with this?

The filter side was really good condition

Ok, so I thought must be somewhere else and opened up the cooler side. Indeed, there was a small paint chip missing near the backflow tube.

Naturally I assumed that this is only the beginning and it is on the verge of totally peeling away. But was I wrong, after two days and probably like 15 times with 3 different paint removers this is where I am...

The damn paint just wont come off. So the question is it now too late to turn back and assemble everything as it is, or will it now definitely start to peel away bit by bit?

At the same time, the waterjacket side seems to have pitting just in the places where the O-rings would sit. Will it it hold or will I have leaks?

Any recommendations on how to move on with this?