Re: Fuel Fill Repair?

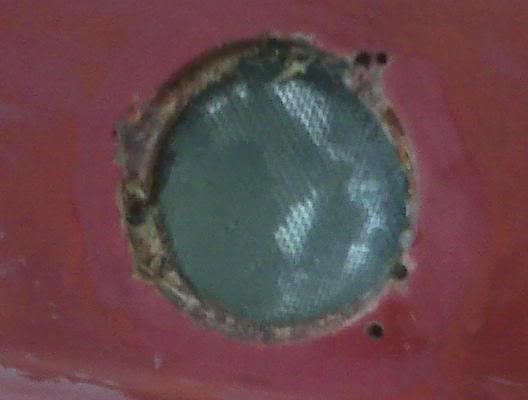

Yes, you can put in 1/4" luan. I would remove the glass on the back covering the hole (grind area smooth), then fit in the luan, apply new layer of glass front and back all at the same time. That will give the best lamination and least amount of air bubbles, etc. After that sets, a few more layers can be built up. Then sand smooth, cut the new hole, and your set.

Trying to fit in the luan over the new glass you put in will not make a good bond because the new glass is not smooth and is already stiff with resin.

Another approach is to get the bondo resin with chopped strand glass mixed in. Then mix up a batch and smear it into the hole over the new piece of glass you have in there now. Let it cure and grind smooth, then cut the new hole for the filler, etc.

Which ever way you do it, I think it would be a good idea to epoxy a 1/2" piece of plywood over the hole from behind to reinforce it (maybe 4x6 or 4x8" piece). Cut the new hole through the plywood, and use long screws to attach the new filler neck. Remember, there is often a lot of lateral stress on a filler neck as people sometimes lean on the filler nozzle while filling, and that stress goes directly to the filler neck. Without any reinforcement, the new repairs could easily crack out. You can use the epoxy in the double tube applicators from the home centers. It will work well for this fix. This is also a good application for pressure treated ply, because the fuel fill is a place where water often leaks in. Don't forget to use a good marine grade sealer like boat life or 3m 4200 on the filler neck.