I scratching my head and seeking help.

I have a 1991 Seaswirl 190 I/O with an OMC 5.0 (302 Ford engine) and a Holley 2300 2bbl carburetor. Salt water had gotten into the gas tank and I drained the tank and rebuilt the carburetor. Now, the engine starts and idles fine. However, here are the problems:

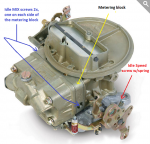

1) The idle adjustment screw on the starboard side of the carburetor will kill the engine if turned all the way in. The idle adjustment screw on the port side does nothing to the engine if I turn it all the way in or even take it out.

2) If I accelerate the throttle (while on muffs), I will see gas coming from the carburetor venturi or the port side but no gas comes out of the venturi on the starboard side while accelerating.

3) When running the boat with throttle open to about 1800 rpm, a rich condition is present and black soot comes out of the exhaust.

I have adjusted the float. It appears to me that if it were a float problem, there would be a problem with both idle adjustment screws, not just one. I put in a 3.5 powervalve. I believe it is a vacuum leak somewhere. I sprayed WD40 all around the base and the carburetor without the carburetor increasing in rpm.

I'm hoping to find a solution.

I have a 1991 Seaswirl 190 I/O with an OMC 5.0 (302 Ford engine) and a Holley 2300 2bbl carburetor. Salt water had gotten into the gas tank and I drained the tank and rebuilt the carburetor. Now, the engine starts and idles fine. However, here are the problems:

1) The idle adjustment screw on the starboard side of the carburetor will kill the engine if turned all the way in. The idle adjustment screw on the port side does nothing to the engine if I turn it all the way in or even take it out.

2) If I accelerate the throttle (while on muffs), I will see gas coming from the carburetor venturi or the port side but no gas comes out of the venturi on the starboard side while accelerating.

3) When running the boat with throttle open to about 1800 rpm, a rich condition is present and black soot comes out of the exhaust.

I have adjusted the float. It appears to me that if it were a float problem, there would be a problem with both idle adjustment screws, not just one. I put in a 3.5 powervalve. I believe it is a vacuum leak somewhere. I sprayed WD40 all around the base and the carburetor without the carburetor increasing in rpm.

I'm hoping to find a solution.

Last edited: