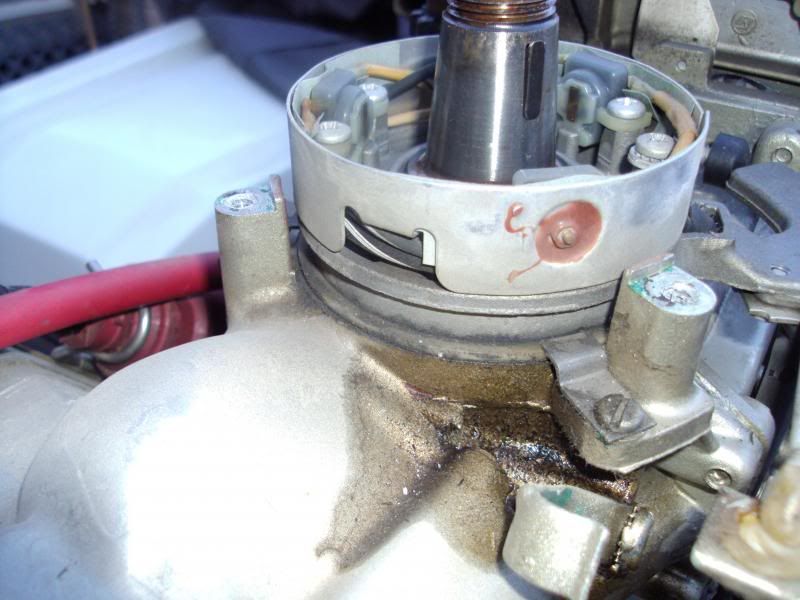

boating along....engine just quit...got towed home. Tested spark...no spark on all 3 cyl. I got onto the CDI website and it stated to check for oil coming from area near stator......sure enough a coat of light oil leaking from stator area below flywheel on engine block. I went ahead and ordered a stator prematurely....that i now know, but also read that these evinrudes were prone to bad stators. The bit of oil (flywheel now removed)seems to be coming from below the trigger coil.

Anyway...my first question is ......after looking through an online older evinrude manual, it states to follow testing procedures as follows....

test #1 ignition coil output check

test #2 trigger coil output check

test #3 charge coil output check

test #4 power pack output check

test #5 key switch check

test #6 sensor coil low ohm check

So tell me, ...are these older manuals of value or are there better/faster ways of troubleshooting. I guess im wondering if there are shortcuts used now a days to speed up testing things. any help would be great. I would take this to a shop but lyme disease took care of that so my brain is getting a good work out with this, to say the least...lol. still have my sense of humor though. And no...i do not own a compression testor that works at the moment. Thanks

Anyway...my first question is ......after looking through an online older evinrude manual, it states to follow testing procedures as follows....

test #1 ignition coil output check

test #2 trigger coil output check

test #3 charge coil output check

test #4 power pack output check

test #5 key switch check

test #6 sensor coil low ohm check

So tell me, ...are these older manuals of value or are there better/faster ways of troubleshooting. I guess im wondering if there are shortcuts used now a days to speed up testing things. any help would be great. I would take this to a shop but lyme disease took care of that so my brain is getting a good work out with this, to say the least...lol. still have my sense of humor though. And no...i do not own a compression testor that works at the moment. Thanks

Last edited: