sourbsted

Petty Officer 1st Class

- Joined

- Jul 15, 2006

- Messages

- 216

I have a 73 mercury blueband 150hp ser: 8008578. I have the mercury workshop manual, which I have been following. The carbs have been rebuilt, fuel pumps rebuilt, new timing belt, cleaned all the electrical connections. All cylinders have compression between 140-150psi.

The boat struggles to plain out, hesitates through low rpm then, if i'm lucky it will plane out and go hard like a young dog off a lead. I have been told by everyone I NEED to do the link&sync.

I'm stuck on this link&sync procedure.

- Reverse boat on trailer into water, start it warm it up

- Starts good on fast idle, doesnt idle 100% cause I would need to adjust the idle mixtures. At this stage they are set at 1 1/4 turns out.

- Here's my problem: I obviously want to adjust the "primary throttle pickup" to get the hole shot test better. I CANNOT get to BTDC 4-6 degree's like I am suppose to. At very low idle it stays at ATDC 10 degree's. If I try to lower the idle any more it just goes straight to BTDC 464 degrees then stalls. Am I missing something here or what?

- At TDC I have the alignment pointer aimed at Zero on the flywheel. Just like I do any other engine I have ever worked on. It's hard to figure out what to do in the workshop manual cause, they go on about serial numbers.

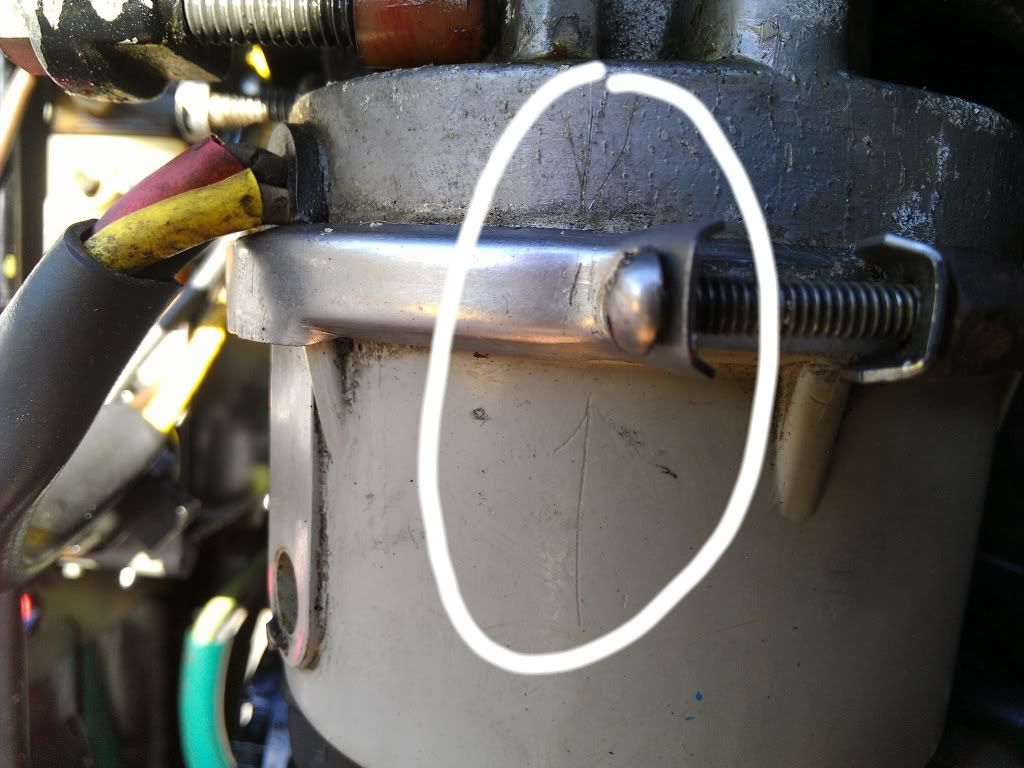

I have changed the timing pointer so it aligns with the zero on the flywheel. It may have aligned on the BTDC 4 degree's before I changed it.

Am I suppose to change the pointer so rather than pointing at ATDC 10 degrees on idle, change the pointer so it's on BTDC 4 degree's.??

Obviously if I didnt have to work for a living I would figure it out. And I tryed to find someone to work on it but they refuse to work on it because of it's age, told me to wait to the off season when their work dies down a bit.

The boat struggles to plain out, hesitates through low rpm then, if i'm lucky it will plane out and go hard like a young dog off a lead. I have been told by everyone I NEED to do the link&sync.

I'm stuck on this link&sync procedure.

- Reverse boat on trailer into water, start it warm it up

- Starts good on fast idle, doesnt idle 100% cause I would need to adjust the idle mixtures. At this stage they are set at 1 1/4 turns out.

- Here's my problem: I obviously want to adjust the "primary throttle pickup" to get the hole shot test better. I CANNOT get to BTDC 4-6 degree's like I am suppose to. At very low idle it stays at ATDC 10 degree's. If I try to lower the idle any more it just goes straight to BTDC 464 degrees then stalls. Am I missing something here or what?

- At TDC I have the alignment pointer aimed at Zero on the flywheel. Just like I do any other engine I have ever worked on. It's hard to figure out what to do in the workshop manual cause, they go on about serial numbers.

I have changed the timing pointer so it aligns with the zero on the flywheel. It may have aligned on the BTDC 4 degree's before I changed it.

Am I suppose to change the pointer so rather than pointing at ATDC 10 degrees on idle, change the pointer so it's on BTDC 4 degree's.??

Obviously if I didnt have to work for a living I would figure it out. And I tryed to find someone to work on it but they refuse to work on it because of it's age, told me to wait to the off season when their work dies down a bit.