Miller4519

Cadet

- Joined

- Jul 6, 2017

- Messages

- 19

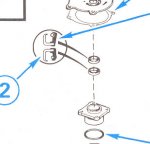

So I dropped my lower unit and opened it up because it wasn't catching forward and reverse like it should. The previous owner had filled it with bearing grease from the looks of it. I used brake cleaner to get all that gunk out. I could not find the seal kit for my motor listed anywhere so I purchased Sierra kit 18-2684 because it fit the Johnson 18hp from 1958. It can't be that different? I pulled the top oil seal and it was a soild thick piece of brass with a very worn rubber center. In the kit there are two thin pieces that are the same diameter with an open back to them. Together they equal the same thickness as the original brass piece I pulled from my motor. Does anyone know if I can use both of those pieces in it's place? I assume the open ends would mate to one and other.

Last edited: