First time taking out a new to me boat today. 2015 Bayliner 175 i/o. Drove the boat for about an hour and noticed a small amount in the bilge, maybe 1” or so. Boat sat at the dock for 4 hours and thankfully I checked, bilge was pretty much full, maybe 6”.

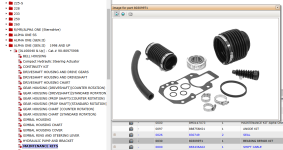

It wasn’t obvious to me where the water infiltration was coming from. What do y’all think is the most likely source, bellows? As far as I know, the bellows are original. I visually inspected the bellows when I had the outdrive off recently, and the rubber looked really good, no signs of cracking, so I didn’t replace despite being 10 years old.

It wasn’t obvious to me where the water infiltration was coming from. What do y’all think is the most likely source, bellows? As far as I know, the bellows are original. I visually inspected the bellows when I had the outdrive off recently, and the rubber looked really good, no signs of cracking, so I didn’t replace despite being 10 years old.