Ok, i recently bought a pontoon with a mercruiser 3.0 I/O that had blown the head gasket 3 times. I am a jet mechanic by trade so i know how to turn a wrench but not so experienced on boat or car motors, so i took the engine apart and had it bored, decked, the head rebuilt, installed all new pistons, cam, timing gears, bearings, ect. rods were checked by machine shop, block tanked. When changing the drive water pump impeller i found the water tube melted and the teeth on the impeller broke off, so i assume that is why the last guy kept blowing heads. this is a 2001 parti kraft 24 ft pontoon with the merc 3.0 and alpha one gen 2 drive.

So i get the motor back in the boat and take it to the lake, starts and idles great, purs like a kitten. idle it around the ramp area for a little while and then head out to open water running varied rpms up to 4000, runs great and i am real happy at this point so i push it a little more up to about 4600 rpm to play with the trim and see where it planes out at and then crap started.

keep in mind the oil pressure always stayed about 40-45 psi while above idle and engine temp stayed at or below 160, neither fluctuated even during my problems.brand new gauges checked both prior to running engine.

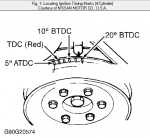

It started by loosing power, i throttled back to about 2000 rpm then back up to 3000 and its started sounding like it was bogging out. so i pull off to the side at idle and it dies on me and will not fire again. i pop the hatch to the engine and the bilge toon has oil in it, the back of the motor was soaked.it appears it all came out of the rocker cover breather elbow. Yes it was properly service prior and when i broke down i did add two quarts to bring it back to full. i could not get it started again until i rotated the distributor about 3/4" of an inch to the right (advancing the timing) then it fired right up but it has a deep engine knocking sound. now.i cannot remember if the knocking started when it bogged down or after i moved the distributor, i limped it back to the dock at idle and oil press and water temp were good, never changed more than 5 psi for oil and 10 degrees for engine temp. i took the valve cover off and checked the rockers and push rods and all were good. the knock increased in frequency with the throttle but did not get louder.it is definetly not a ping or ting or click, or tick, It is a metal to metal clank or knock. I have read a bunch of other threads on this forum and another site about engine noise with this engine, from timing ping, to fuel pump eccentric arm, to rocker arm adjustment.

this all happened yesterday and i had to go back to work tonight, so i have not had time to look at it too close. With the details above i am looking for suggestions before i rip the engine out ....again.

I assume i threw a rod bearing, but have a few questions

1. why did it only spit heavy oil at WOT? it did not vent oil from the breather until i went over 4000 rpm and even after the engine started knocking it did not vent any oil the rest of the time, none

2. why did it loose timing? i only adjusted it 3/4" and it idled perfect again ( other than knock), i know it didn't move by itself because i painted alignment marks when i timed it before we tried it on the water.

3. is there anything you can think of before i pull the motor?

So i get the motor back in the boat and take it to the lake, starts and idles great, purs like a kitten. idle it around the ramp area for a little while and then head out to open water running varied rpms up to 4000, runs great and i am real happy at this point so i push it a little more up to about 4600 rpm to play with the trim and see where it planes out at and then crap started.

keep in mind the oil pressure always stayed about 40-45 psi while above idle and engine temp stayed at or below 160, neither fluctuated even during my problems.brand new gauges checked both prior to running engine.

It started by loosing power, i throttled back to about 2000 rpm then back up to 3000 and its started sounding like it was bogging out. so i pull off to the side at idle and it dies on me and will not fire again. i pop the hatch to the engine and the bilge toon has oil in it, the back of the motor was soaked.it appears it all came out of the rocker cover breather elbow. Yes it was properly service prior and when i broke down i did add two quarts to bring it back to full. i could not get it started again until i rotated the distributor about 3/4" of an inch to the right (advancing the timing) then it fired right up but it has a deep engine knocking sound. now.i cannot remember if the knocking started when it bogged down or after i moved the distributor, i limped it back to the dock at idle and oil press and water temp were good, never changed more than 5 psi for oil and 10 degrees for engine temp. i took the valve cover off and checked the rockers and push rods and all were good. the knock increased in frequency with the throttle but did not get louder.it is definetly not a ping or ting or click, or tick, It is a metal to metal clank or knock. I have read a bunch of other threads on this forum and another site about engine noise with this engine, from timing ping, to fuel pump eccentric arm, to rocker arm adjustment.

this all happened yesterday and i had to go back to work tonight, so i have not had time to look at it too close. With the details above i am looking for suggestions before i rip the engine out ....again.

I assume i threw a rod bearing, but have a few questions

1. why did it only spit heavy oil at WOT? it did not vent oil from the breather until i went over 4000 rpm and even after the engine started knocking it did not vent any oil the rest of the time, none

2. why did it loose timing? i only adjusted it 3/4" and it idled perfect again ( other than knock), i know it didn't move by itself because i painted alignment marks when i timed it before we tried it on the water.

3. is there anything you can think of before i pull the motor?