I'm in the process of restoring stringers and transom for a 20ft cuddy cabin. The old engine mounts are closed boxes made out of 1/2"ply. 3 sides + lid glassed to stringer. A 6x8 wood core snuggly sitting in there ( but not attached to anything, I think its only purpose is to hold the lag screws and press the engine against the mount box).

When opening it, the wood was soaked/rotten but the fiberglass completely fine ( no cracks, mounts where completely filled with water ). I think it entered over time through the mount screw holes.

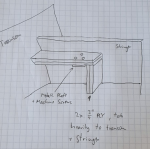

Do you have any tips or a link for a better technique ? Something where the wood is protected. I saw a couple mounts that where like bridges, not closed boxes. Ideally pre drilled glassed holes and then using an aluminum back plate + machine bolts + nuts instead of screwing directly into the wood. But idk if that bridge looking design is sufficient for a stringer 800 outdrive as it doesn't push the transom but directly the motor mounts.

I also got 5gal of seacast standing around. I don't want the whole mount made out of seacast but maybe only the parts that are under the motor feet holding the screws.

When opening it, the wood was soaked/rotten but the fiberglass completely fine ( no cracks, mounts where completely filled with water ). I think it entered over time through the mount screw holes.

Do you have any tips or a link for a better technique ? Something where the wood is protected. I saw a couple mounts that where like bridges, not closed boxes. Ideally pre drilled glassed holes and then using an aluminum back plate + machine bolts + nuts instead of screwing directly into the wood. But idk if that bridge looking design is sufficient for a stringer 800 outdrive as it doesn't push the transom but directly the motor mounts.

I also got 5gal of seacast standing around. I don't want the whole mount made out of seacast but maybe only the parts that are under the motor feet holding the screws.