Hi, I got this motor (model SC-10S) after it was sitting 5-7 years in the basement.

It had good compression, so decided to fix it.

It did not have spark.

So, new coil, condenser, point, spark plug wire and plug..

Soaked and rebuilt carb with carb new kit, new fuel line.

New impeller.

That is like 3/4 of the motor is new now.

It starts with first pull and idles at 550-560 rpms as per manual.

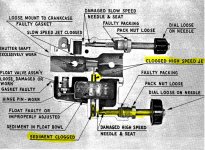

Now the problem: when I start to move armature plate to fast it speeds up to about 900-1000 rpms and stalls.

Can not make it to run fast.

Any advice/idea why?

thanks.

It had good compression, so decided to fix it.

It did not have spark.

So, new coil, condenser, point, spark plug wire and plug..

Soaked and rebuilt carb with carb new kit, new fuel line.

New impeller.

That is like 3/4 of the motor is new now.

It starts with first pull and idles at 550-560 rpms as per manual.

Now the problem: when I start to move armature plate to fast it speeds up to about 900-1000 rpms and stalls.

Can not make it to run fast.

Any advice/idea why?

thanks.