Bruiser61

Cadet

- Joined

- Aug 6, 2018

- Messages

- 6

I've visited your forums many times over the last few years. I've always found it informative and spot on.

I recently got a pretty sweet deal on a 1990 Key West 1700 dual console with a 1978 Mercury model 800.

The hull was in very good condition for it's age. A few chips, gouges, dings and light spiderweb cracks. NO soft spots!!

The motor? Not so good. PO had started to working on it. As with most old mercs, the wiring crumbled at the slightest touch. Many wires were completely gone. Many wires just disconnected and hanging there. Lower unit removed, controls disconnected, etc.

The PO was in way over his head (more than I).

Because of the information on this forum and prior experience, I have been able to take care of a lot of the issues.

New stator and trigger assemblies.

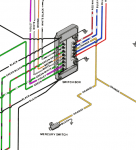

Rewired the entire boat. I even found some household extension cord spliced in under the deck!!!

I'm getting close to completion. Just some problems I can't seem to work through. Hoping someone can offer the solution.

I do have a lot of pics, but I'm at work now and can't upload them. I will try to add them later today.

I've tried to get the lower unit back on (after replacing the impeller), no matter what I do, I can't get it to mate up with the mid section. About a half inch gap.

The mercury switch was gone. I replaced it. One wire to ground, the other???

The trim/tilt pump chatters in one direction like the solenoid is no good. I've tried two different solenoids with the same results.

Thanks in advance for you help and input!

I recently got a pretty sweet deal on a 1990 Key West 1700 dual console with a 1978 Mercury model 800.

The hull was in very good condition for it's age. A few chips, gouges, dings and light spiderweb cracks. NO soft spots!!

The motor? Not so good. PO had started to working on it. As with most old mercs, the wiring crumbled at the slightest touch. Many wires were completely gone. Many wires just disconnected and hanging there. Lower unit removed, controls disconnected, etc.

The PO was in way over his head (more than I).

Because of the information on this forum and prior experience, I have been able to take care of a lot of the issues.

New stator and trigger assemblies.

Rewired the entire boat. I even found some household extension cord spliced in under the deck!!!

I'm getting close to completion. Just some problems I can't seem to work through. Hoping someone can offer the solution.

I do have a lot of pics, but I'm at work now and can't upload them. I will try to add them later today.

I've tried to get the lower unit back on (after replacing the impeller), no matter what I do, I can't get it to mate up with the mid section. About a half inch gap.

The mercury switch was gone. I replaced it. One wire to ground, the other???

The trim/tilt pump chatters in one direction like the solenoid is no good. I've tried two different solenoids with the same results.

Thanks in advance for you help and input!