Help! Replacing a fuel pump on an 91 5.8:L Ford with a 4 barrel. I found what should have been the matching part but the ports into and out of the pump do not line up with the original. They will not line up with the hard lines that come from the filter and to the carburetor.

Engine 584APLRGD , Fuel pump per the Crowley Marine site 3854053 or 0987024 .

Link: https://www.crowleymarine.com/johnson-evinrude/parts/56214.cfm?mdl=4RU8CJ

I found the pump here: https://www.offshoremarineparts.com/62-32-053.html

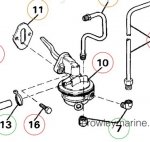

I do see that the replacement pump looks just like the picture on the Crowley site item #10 Note the port positions.

The problem is that my old pump does not have the port the same as even the crowley picture.

See pictures. This is a 91 engine on a 92 boat but I think everything is stock. Why is my pump different???

I was even hoping that I could remove the lower section of the new pump, and rotate it 1 screw hole and put it back. But that would not line up either. If you look closely at the screw holes you can see that.

Help

Engine 584APLRGD , Fuel pump per the Crowley Marine site 3854053 or 0987024 .

Link: https://www.crowleymarine.com/johnson-evinrude/parts/56214.cfm?mdl=4RU8CJ

I found the pump here: https://www.offshoremarineparts.com/62-32-053.html

I do see that the replacement pump looks just like the picture on the Crowley site item #10 Note the port positions.

The problem is that my old pump does not have the port the same as even the crowley picture.

See pictures. This is a 91 engine on a 92 boat but I think everything is stock. Why is my pump different???

I was even hoping that I could remove the lower section of the new pump, and rotate it 1 screw hole and put it back. But that would not line up either. If you look closely at the screw holes you can see that.

Help