Re: Pinewood Derby Time

The best things I picked up that my son and I did on his car were.

- True the axles on a drill press, chuck up an axle and spin it in the drill press while holding a screw driver on the side of the axle, it should feel perfectly smooth, not hopping. If it hops, you need to tweek the axle a bit so it runs true.

- True the axle/nail heads with a fine file to take off any high spots off the head.

- Polish the axles on a drill press, WD40 and progressively higher grit sand paper ending at 2000 grit. Once it's smooth with 2000 grit, hit it with some polishing compound and denim jean material.

- Chuck up a wheel in a "wheel jig" and sand the tread of the perfectly flat and true with progressively finer sand paper and WD40 ending at 2000 grit. You will need a square block of wood to rest the sand paper on so you are sanding the wheel against the block of wood, while the wheel is in the drill press.

- Polish the wheel bores with polishing compound. Chuck up a pipe cleaner in the drill press, slather it with polishing compound, push wheel onto pipe cleaner, turn on drill press and run wheel up-down the pipe cleaner reapplying polishing compound a few times.

- As tx posted, 1 of the front wheels should be "lifted" and the car should be balanced so it rides on 3 wheels. We set one of the front wheels 1/8" higher and it would ride without that wheel touching most of the time.

- Move the axle locations so the wheels are even with the front and back of the car. We clamped a block onto the drill press so all axle holes were at the same heigth,,, well except 1 of the front wheels.

- For weights, drill a couple holes in a board with a Forstner drill bit, grab a couple 1oz and 1/2 oz fishing sinkers, drive a screw driver into the sinkers line hole (for a handle) and then melt the lead into the holes. This makes perfect 1oz and 1/2 oz weights, I think we used 1" and 3/4" Forstner bits. Fine tuning the car's weight can be done with regular sinkers.

- Weight placement was between 2/3 and 3/4 back, right in front of the rear axle. Use the Forstner bit to drill holes for the lead slugs you just made, the slugs will be a touch loose as the slugs shrink when they cool, epoxy them into the body.

- Fine tuning weight can be done with a electronic scale, I picked one up from Harbor Freight for $20 and he dialed the car into just shy of 5 oz, it was like 4.99999999999oz

The fine tuning weights should be siliconed into the body,,, just in case the "official" scale is slightly different.

-Gap the wheels, we used a credit card for wheel to body clearance.

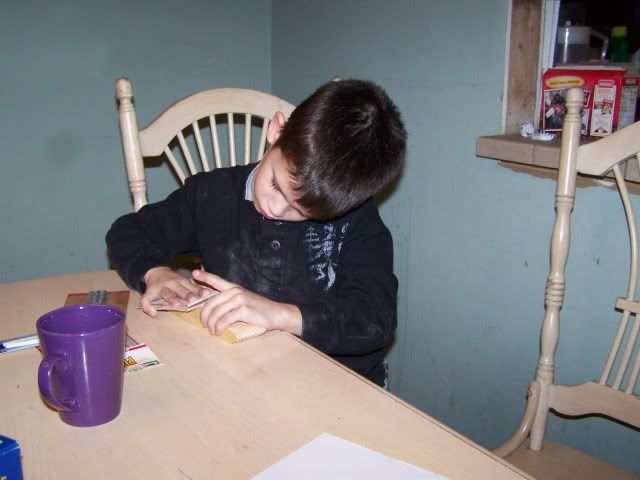

I would say we put as much time into the axles/wheels as the rest of the car. I would show him how to do 1, then he would do the other 3. He pretty much did the entire body on his own (under close supervision) as he was using some power tools, mostly hand tools though.

In our pack, the last chance you have to do anything to the car is at weigh-in, so graphite your wheels 1 last time before weight in. Once you finally weigh in, they take the car and store it until race day.

I think it took us 10-15 hours to make the car, but it was worth it. His first year he won 1st place! The pack leader build a "hotrod" car, just for messing around, and after the races were finished the pack leader wanted to race my son's car... I think he raced my sons car 8-10 times, but he never won.

I got the feeling they thought we "cheated", but I knew he did 90% of the work on the car. I guess it's his fault his dad is a woodworking/mechanical nut...

don't tell) was actually for my daughter then for one of her friends in the girl scouts.her mother was my secretary.

don't tell) was actually for my daughter then for one of her friends in the girl scouts.her mother was my secretary.