catfishhoward

Petty Officer 2nd Class

- Joined

- Oct 9, 2009

- Messages

- 136

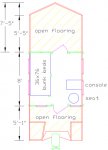

I have a 1990 Bass Buggy DL, I want to get rid of the hard top and all the seats and seal the floor and build a small bldg with bunk beds and was worried about the correct location to put it so it rides the best and if the boat would even hold the weight with the 21" toons. I figure it would be built with 2" x 3" studs, 3/8" shed wood siding and a flat rubber roof and would be be 8' x 8' which with the bunk beds the bldg would be about 750lb's. With the bldg, 3 people, batteries, gas, flooring, handrails, 60 hp Johnson and everything else around 2300lb. I think the 20.5' x 21" toons are rated to hold 2700lb's +/- half immersed? I've attached some sketches of what I've come up with and would like your info If this could be done structurally safe or if you see a better way of doing it. I plan on using for weekend trips camping and fishing on calm lakes in Georgia, no tubing, just 2 mile trips from the boat launch to drop anchor.

I ran the numbers using 1.5" aluminum square tube for the main structure and it was only about 100lbs lighter since I would have to L bracket and bolt everything together and it would cost about $700 more than the 2" x 3" wood, so I'm not thinking aluminum.

The hard top coming off is about 60lbs, railing coming off is about 20lbs and I'm not sure what the seats all weight but at least 300lbs so I'll have at least 350lbs coming off, so from the picture water line I've attached I would only be adding about 400lbs and also I will be shifting the building towards the front 2.5' to give me a fishing platform in back and try to level out the weight. I figure I can move the batteries to the front as well.

I ran the numbers using 1.5" aluminum square tube for the main structure and it was only about 100lbs lighter since I would have to L bracket and bolt everything together and it would cost about $700 more than the 2" x 3" wood, so I'm not thinking aluminum.

The hard top coming off is about 60lbs, railing coming off is about 20lbs and I'm not sure what the seats all weight but at least 300lbs so I'll have at least 350lbs coming off, so from the picture water line I've attached I would only be adding about 400lbs and also I will be shifting the building towards the front 2.5' to give me a fishing platform in back and try to level out the weight. I figure I can move the batteries to the front as well.

Attachments

Last edited: