Re: Rectifier Replacement

I felt the same way as you, but since there isn't a reasonable evinrude mechanic near me, I just pulled the trigger and got the OEM puller. I found it on ebay for a good price though (new is like $70+). The puller and the strap wrench are critical. Make sure you have a socket big enough for the flywheel nut (most medium sized socket sets will NOT have one large enough).

The hardest parts are breaking the flywheel nut and pulling the flywheel with the puller. I broke the nut myself with an extension bar and sort of "wedging" the strap wrench under the flywheel and over the power pack. You have to be mindful of where your flywheel magnets are when doing this...not an issue with my flywheel.

Pulling was techincally easier, but I had a friend stop by on lunch break to hold an extension bar on the strap wrench while I used an extension bar to tighten down the puller. A few twists later and it popped. Took about 5 minutes with his help. My extension bars are just scrap metal tubes from various pieces of trash (old snow shovel handle, old sun umbrella tube). The wife said I was nuts when I saved them, but she wasn't complaining when we were back out on the water!

If it just won't budge, I've heard an impact wrench can make short work of this step. If you don't have one and can't borrow one, you might be able to take it up to a local mechanic and pay him a few bucks to break it for you real quick.

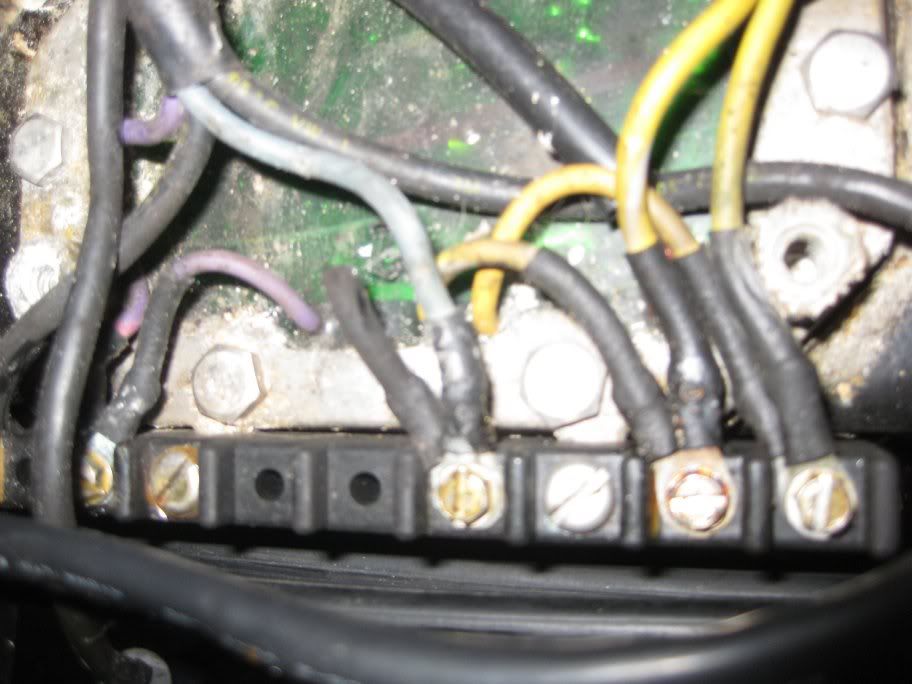

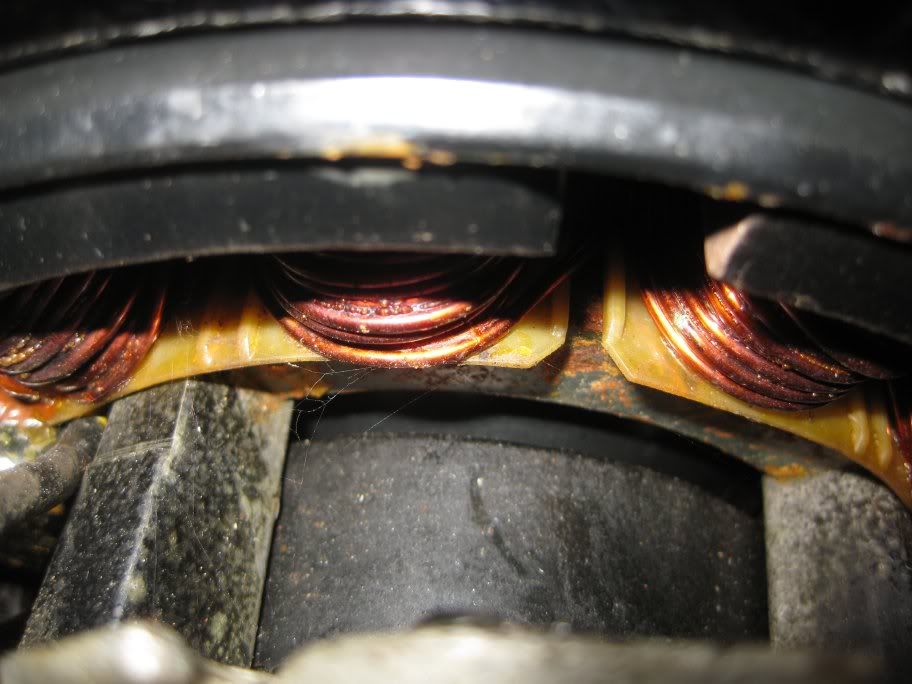

The rest is ridiculously easy...just follow the manual AND the specific parts instructions. While you're at it, since you'll probably have to remove the stator to get at the reg/rect, check it out too. Do the ohms resistance tests and check for any "black goo" that isn't just normal electrical sealant. Be sure to use a thread locker as stated in the manual when putting the stator back on.

It seemed like a monumental task for such a simple replacement, but once you've done it once, you'll be able to do it again and know exactly how to work with your specific engine. If you're a DIYer like me, I say go for it and save the money!

but by the looks of it (without breaking it down) I don?t need to. Just asking so I can prepare to pull it (get a puller) before I start to break it down - if its a must.

but by the looks of it (without breaking it down) I don?t need to. Just asking so I can prepare to pull it (get a puller) before I start to break it down - if its a must.