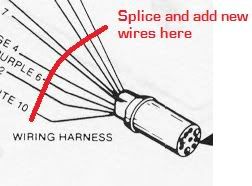

Hey guys, my rebuild is getting close to the time to run some wires (finally!).. I'm working on a boat that is from 1978-1980 (not sure yet) so the wiring is obviously in rough shape. What I want to do is have all fresh wiring in the boat on both the house and the engine side. The house side is no problem, but what I'm wanting to do for the engine side is take the wires where they come out of the wiring harness hookup on the motor (the big round plug with the clamp) and leave about 8-10inches and cut the rest, then take new wires of the same awg and splice them in with polyolephin butt connectors to the original wires so I can have a fresh pieces of wire running to the console. Does that make any sense? I'm wondering if this idea is ok, or should I be doing this a different way? Even if I could find a brand new wiring harness for this old motor, it's $$, and I believe I can do it just as well myself.

The only thing I'm concerned about is that the new wires obviously won't be of the original color codes. To remedy this, I thought about getting a label maker and either use the colored labels that match the original color of the wire, or just write the color(s) on the labels so it will be easier to follow the factory wiring diagrams in the future or if I ever sell the boat.. and put the label on both ends of the wire (at the motor and under the console).

I have tinned marine wire (600ft., greatLakesSkipper), heat-shrink adhesive terminals..

How's that sound? Any advice, ideas, anything??

Thanks!

The only thing I'm concerned about is that the new wires obviously won't be of the original color codes. To remedy this, I thought about getting a label maker and either use the colored labels that match the original color of the wire, or just write the color(s) on the labels so it will be easier to follow the factory wiring diagrams in the future or if I ever sell the boat.. and put the label on both ends of the wire (at the motor and under the console).

I have tinned marine wire (600ft., greatLakesSkipper), heat-shrink adhesive terminals..

How's that sound? Any advice, ideas, anything??

Thanks!