My 2001 Starcraft Fishmaster 176 started leaking badly from a number of rivets.

I pulled the deck only to find that I have cracked welds under the deck between the two front seats. I suspect that these cracked welds are allowing flexing that is causing my loose rivet problems.

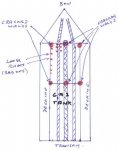

There 5 structural members (stringers?) running fore and aft and 2 ribs that run side to side. The vertical stringers on each side and the ribs are welded in each corner to make a rectangular box. The ribs are then welded to the main stringer running up the keel. All of these welds (6 of them) are cracked (no separation but cracked right through).

I took it in to be repaired. They said re-welding would weaken the structure so they pop-riveted 1 inch aluminum angle brackets over the welds and tightened the loose rivets.

That worked for a short while but now, after 2 months the boat has more loose rivets than before and is leaking like a sieve.

Is this a flaw on this model of boat? Is there a way to fix it? Do I need to reinforce the frame and if so how?

I love this boat and would really appreciate any suggestions for a permanent fix.

I pulled the deck only to find that I have cracked welds under the deck between the two front seats. I suspect that these cracked welds are allowing flexing that is causing my loose rivet problems.

There 5 structural members (stringers?) running fore and aft and 2 ribs that run side to side. The vertical stringers on each side and the ribs are welded in each corner to make a rectangular box. The ribs are then welded to the main stringer running up the keel. All of these welds (6 of them) are cracked (no separation but cracked right through).

I took it in to be repaired. They said re-welding would weaken the structure so they pop-riveted 1 inch aluminum angle brackets over the welds and tightened the loose rivets.

That worked for a short while but now, after 2 months the boat has more loose rivets than before and is leaking like a sieve.

Is this a flaw on this model of boat? Is there a way to fix it? Do I need to reinforce the frame and if so how?

I love this boat and would really appreciate any suggestions for a permanent fix.